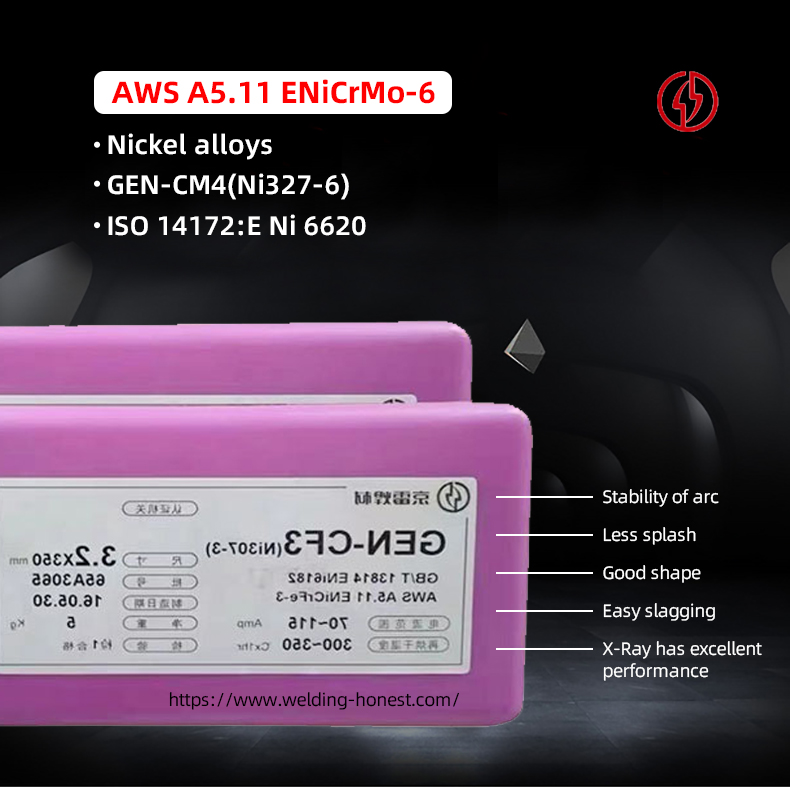

Nickel alloys Manual electrode ENiCrMo-6 weld fabrication jointing

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Fe | W | Nb+Ta | P | S | |

| GB/T RULES | 0.10 | 2.0-4.0 | 1.00 | 12.0-17.0 | ≥55 | 10.00 | 1.0-2.0 | 0.5-2.0 | 0.02 | 0.015 | |

| AWS RULES | 0.10 | 2.0-4.0 | 1.00 | 12.0-17.0 | ≥55 | 10.00 | 1.0-2.0 | 0.5-2.0 | 0.03 | 0.02 | |

| EXAMPLE VALUE | 0.042 | 2.91 | 0.44 | 13.3 | 70.6 | 4.15 | 1.45 | 1.350 | 0.008 | 0.003 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 350 | 620 | - | 32 | ||||

| AWS RULES | - | 620 | - | 20 | ||||

| EXAMPLE VALUE | 450 | 720 | 80/-196 | 40 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||

| ELECTRICITY (Amp) |

H/W | 65-115 | 80-140 | 120-180 | |||||

| O/W | 60-105 | 70-130 | 110-170 | ||||||

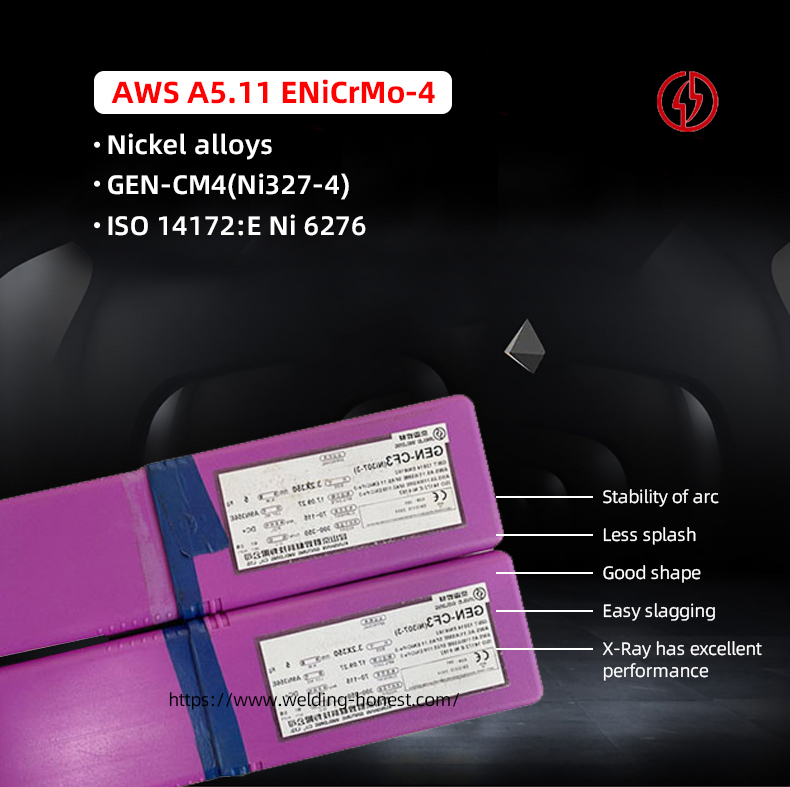

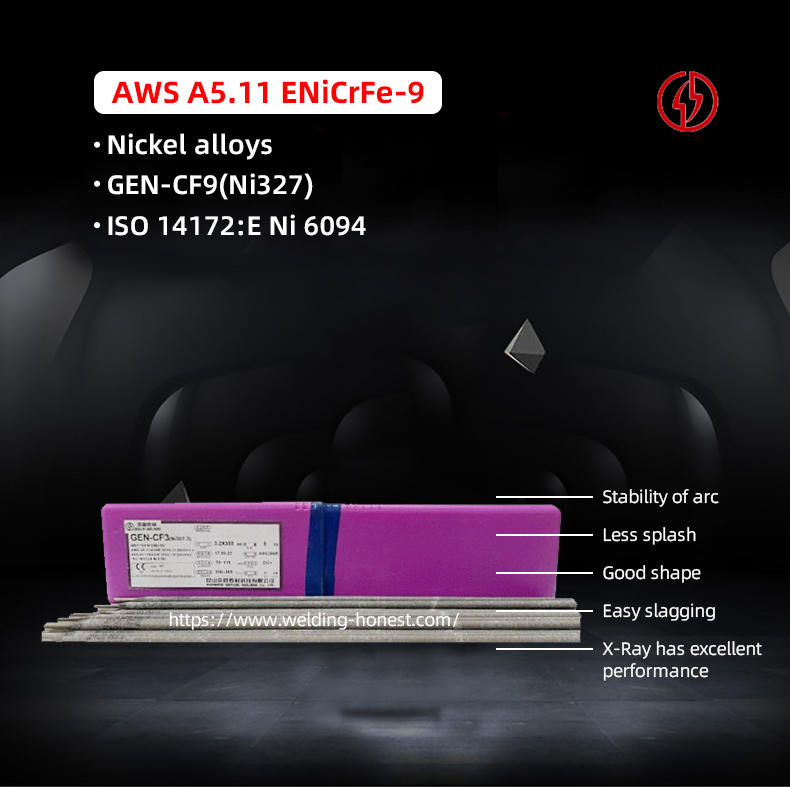

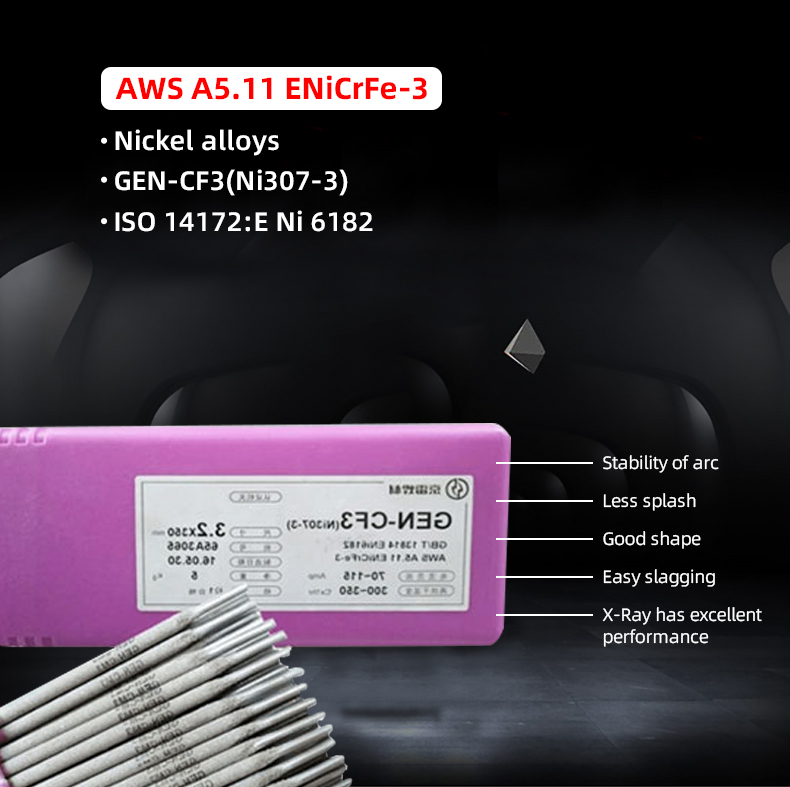

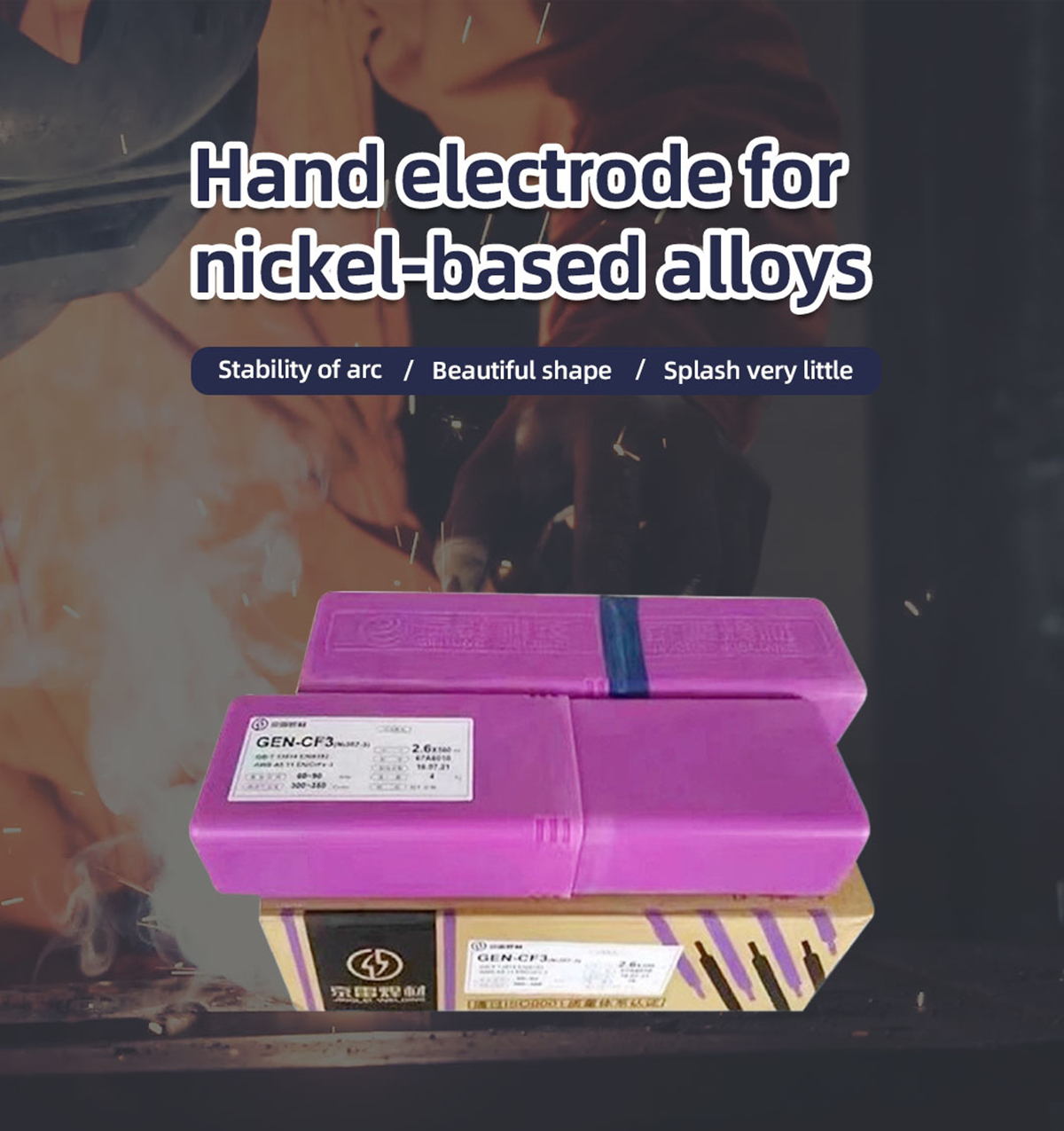

Low hydrogen type hand electrode, nominal composition (weight percent) is 65Ni-14.5Cr-7Fe-7Mo-1.5W-1.5Nb+Ta, nickel-chrome-molybdenum alloy electrode.

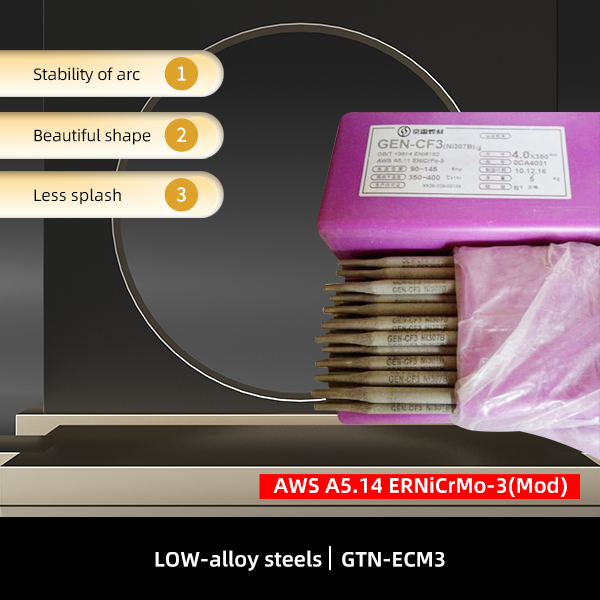

Stable arc, beautiful forming, little splash, easy slag removal, good porosity resistance, the mechanical properties of molten metal is stable.

Low temperature impact toughness is excellent at -196℃, and has a thermal expansion coefficient similar to 9%Ni steel.

-

Shandong Zibo Haiyi 8 sets 3000m³ propylene spherical tank

-

JU2000E jack-up drilling rig

-

85000 m3 Very Large ethane Ethylene Carrier (VLEC)

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Fe | W | Nb+Ta | P | S | |

| GB/T RULES | 0.10 | 2.0-4.0 | 1.00 | 12.0-17.0 | ≥55 | 10.00 | 1.0-2.0 | 0.5-2.0 | 0.02 | 0.015 | |

| AWS RULES | 0.10 | 2.0-4.0 | 1.00 | 12.0-17.0 | ≥55 | 10.00 | 1.0-2.0 | 0.5-2.0 | 0.03 | 0.02 | |

| EXAMPLE VALUE | 0.042 | 2.91 | 0.44 | 13.3 | 70.6 | 4.15 | 1.45 | 1.350 | 0.008 | 0.003 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 350 | 620 | - | 32 | ||||

| AWS RULES | - | 620 | - | 20 | ||||

| EXAMPLE VALUE | 450 | 720 | 80/-196 | 40 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||

| ELECTRICITY (Amp) |

H/W | 65-115 | 80-140 | 120-180 | |||||

| O/W | 60-105 | 70-130 | 110-170 | ||||||

Write your message here and send it to us