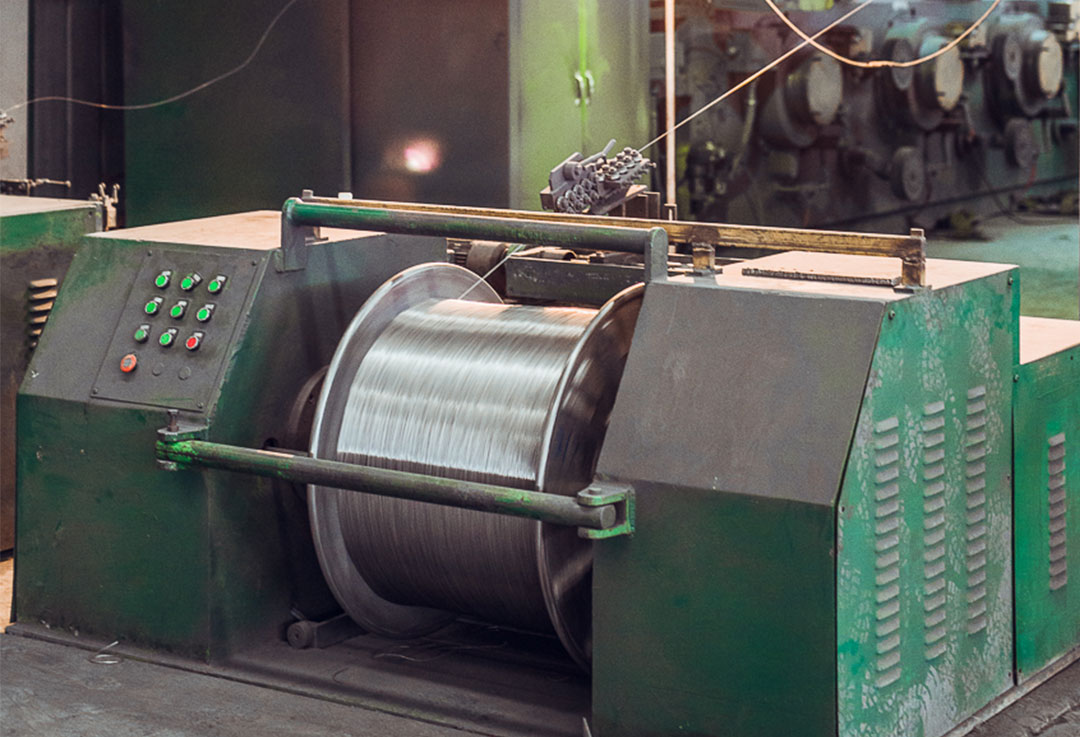

Nickel alloys MIG ERNiCr-3 Soldering connection

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T RULES | 0.10 | 2.5-3.5 | 0.50 | 18.0-22.0 | ≥67 | - | 3.0 | 2.0-3.0 | - | - |

| AWS RULES | 0.10 | 2.5-3.5 | 0.50 | 18.0-22.0 | ≥67 | - | 3.0 | 2.0-3.0 | 0.03 | 0.02 |

| EXAMPLE VALUE | 0.023 | 2.81 | 0.09 | 20.15 | 72.86 | 0.19 | 0.84 | 2.46 | 0.001 | 0.004 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | - | - | - | ||||

| AWS RULES | - | 550 | - | - | ||||

| EXAMPLE VALUE | - | 675 | 92/-196 | 42 | ||||

The main composition is 72Ni-20Cr-3Mn-2.5Nb+Ta, nickel-chromium alloy argon arc welding wire.

Molten metal has good mechanical properties and good resistance to pitting corrosion and crevice corrosion.

Smooth wire feeding, stable arc, beautiful forming, good flow of molten iron, less splash, with excellent welding process performance.

-

85000 m3 Very Large ethane Ethylene Carrier (VLEC)

-

Canada LNG Project

Harbin electric three door CMT

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T RULES | 0.10 | 2.5-3.5 | 0.50 | 18.0-22.0 | ≥67 | - | 3.0 | 2.0-3.0 | - | - |

| AWS RULES | 0.10 | 2.5-3.5 | 0.50 | 18.0-22.0 | ≥67 | - | 3.0 | 2.0-3.0 | 0.03 | 0.02 |

| EXAMPLE VALUE | 0.023 | 2.81 | 0.09 | 20.15 | 72.86 | 0.19 | 0.84 | 2.46 | 0.001 | 0.004 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | - | - | - | ||||

| AWS RULES | - | 550 | - | - | ||||

| EXAMPLE VALUE | - | 675 | 92/-196 | 42 | ||||

Write your message here and send it to us