Nickel alloys MIG ERNiCrMo-3 Soldering makings

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T RULES | 0.10 | 0.50 | 0.50 | 20.0-23.0 | ≥58 | 8.0-10.0 | 5.0 | 3.0-4.2 | - | - |

| AWS RULES | 0.10 | 0.50 | 0.50 | 20.0-23.0 | ≥58 | 8.0-10.0 | 5.0 | 3.15-4.15 | 0.02 | 0.02 |

| EXAMPLE VALUE | 0.006 | 0.15 | 0.15 | 22.01 | 64.80 | 8.72 | 0.18 | 3.49 | 0.001 | 0.001 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | - | - | - | ||||

| AWS RULES | - | - | - | - | ||||

| EXAMPLE VALUE | - | 780 | 144/-196 | 45 | ||||

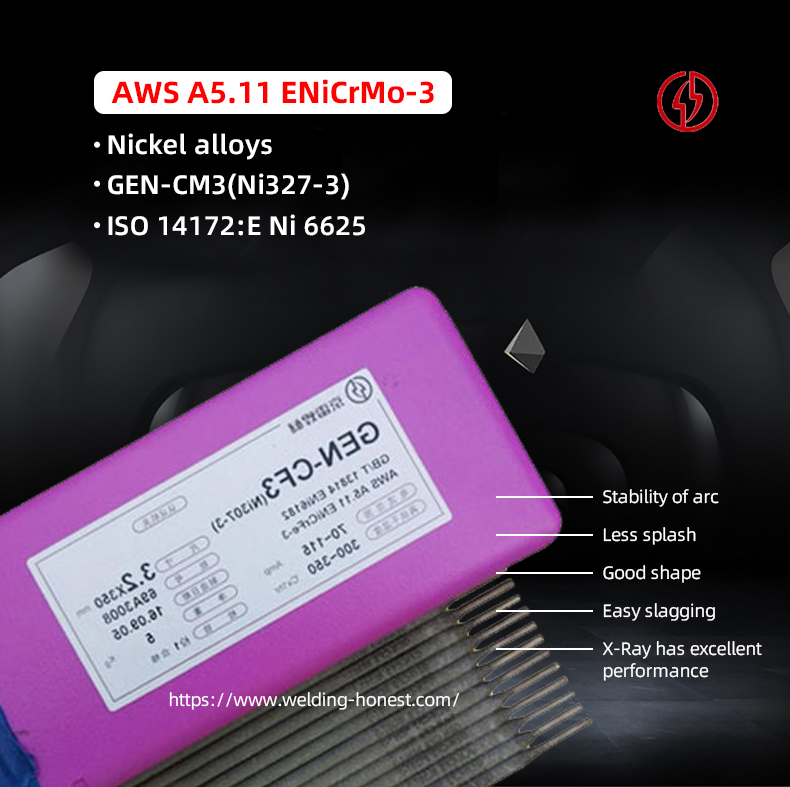

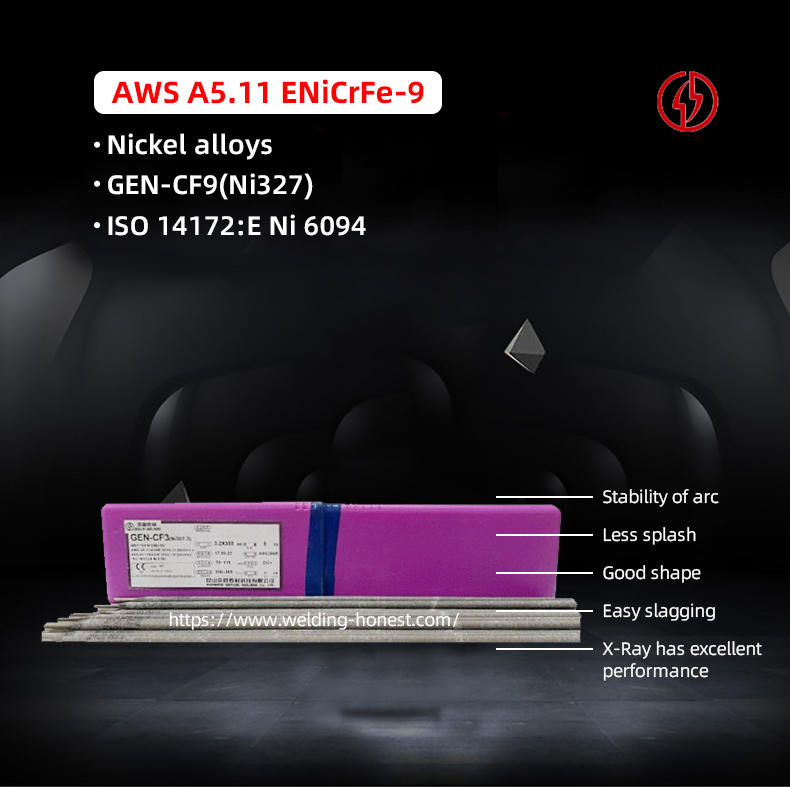

Nickel-chromium-molybdenum nickel-base alloy gas welding wire, nominal composition is 61%Ni-22%Cr-9%Mo-3.5%Nb+Ta.

Good mechanical properties and resistance to pitting and crevice corrosion of molten metal.

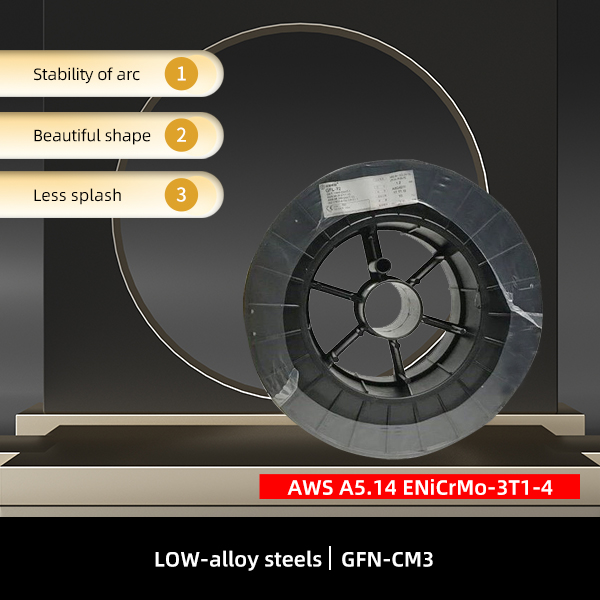

Smooth wire feeding, stable arc, beautiful forming, good flow of hot metal, less splash, with excellent welding process performance.

-

China Global demethane Tower

-

Zhejiang Petrochemical diesel/crude oil storage tank

-

300,000-ton offshore Floating Production and Storage Tanker (FPSO)

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T RULES | 0.10 | 0.50 | 0.50 | 20.0-23.0 | ≥58 | 8.0-10.0 | 5.0 | 3.0-4.2 | - | - |

| AWS RULES | 0.10 | 0.50 | 0.50 | 20.0-23.0 | ≥58 | 8.0-10.0 | 5.0 | 3.15-4.15 | 0.02 | 0.02 |

| EXAMPLE VALUE | 0.006 | 0.15 | 0.15 | 22.01 | 64.80 | 8.72 | 0.18 | 3.49 | 0.001 | 0.001 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | - | - | - | ||||

| AWS RULES | - | - | - | - | ||||

| EXAMPLE VALUE | - | 780 | 144/-196 | 45 | ||||

Write your message here and send it to us