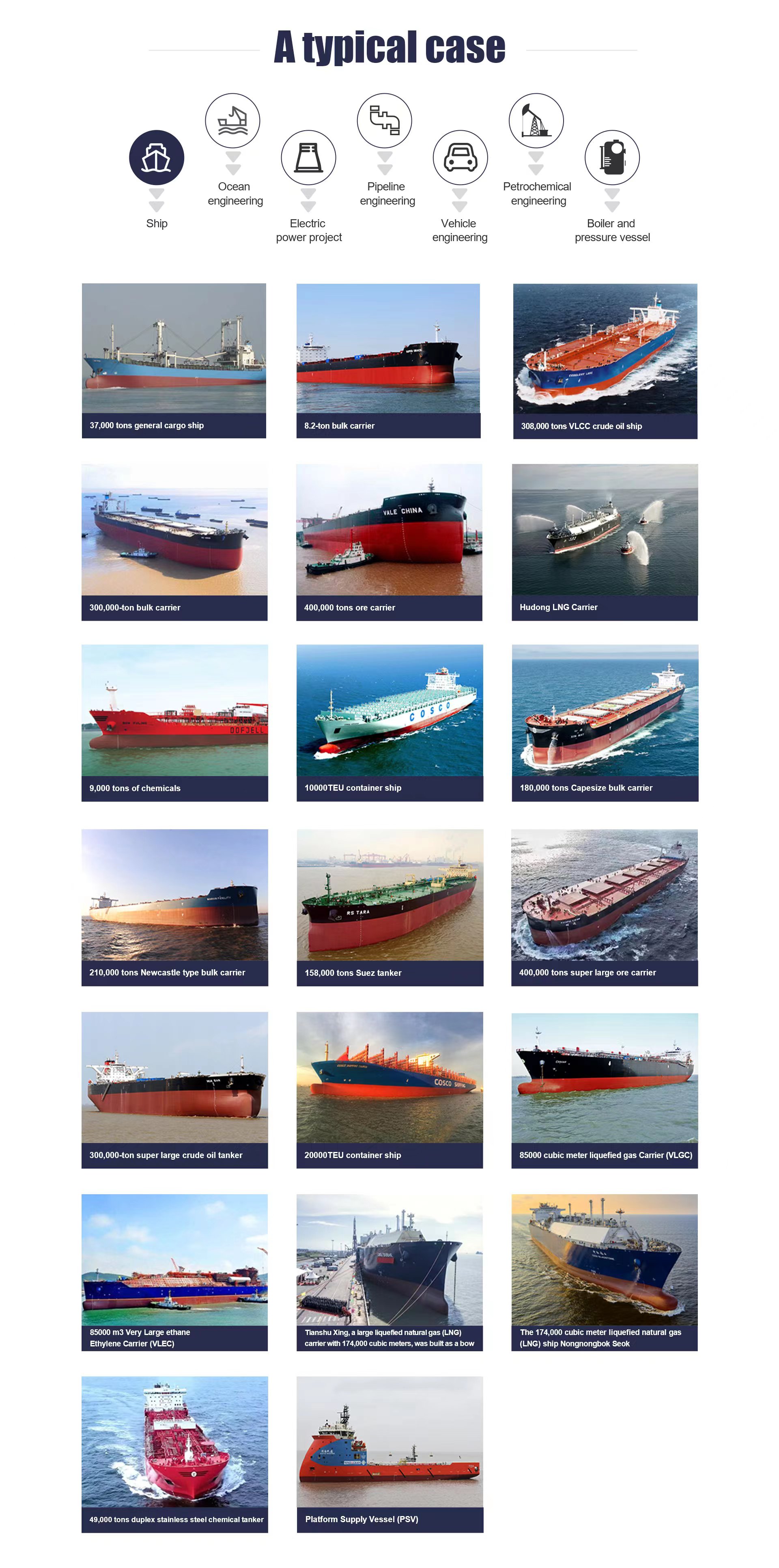

We support ship welding material many years,showing some typical ship project as below

37000tons general cargo ship,8.2-ton bulk carrier,308000tons VLCC oil ship,300000 ton bulk carrier,400000tons ore carrier,Hudong LNG carrier,9000tons of chemicals,10000 TEU container ship,180000 tons capesize bulk carrier,210000 tons newcastle type bulk carrier ,158000 tons Suez tanker,400000 tons super large ore carrier,300000 ton super large crude oil tanker,85000 cubic meter liquefied gas carrier (VLGC),85000 m3 very large ethane ethylene carrier (VLEC),Tianshu Xing ,a large liquefied natural gas (LNG) carrier with 174000 cubic meters ,was built as a bow

The 174000 cubic meter liquefied natural gas (LNG) ship Nongnongbok seok,49000 tons duplex stainless steel chemical tanker,Platform supply vessel(PSV).

The extensive use of high -efficiency welding technology in the field of shipbuilding industry has made the former China Shipbuilding Corporation began to promote and apply high -efficiency welding technology in major shipyards. It has achieved great achievements. In order to improve the quality of hull construction, improve the labor conditions of workers, it plays an important role in shortening the shipbuilding cycle.

Modern high -efficiency welding is generally divided into three categories: melting welding, pressure welding, and welding. The widely used shipbuilding is melting welding

Welding stripe efficient welding:Iron powder welding, downlink welding, gravity welding, stand -by -sided welding.

Automatic welding of buried arcs: single -sided double -sided buried arc automatic welding, welding copper pad multi -filamented arc automatic welding, welded dual -wire buried arc self -welding, soft pad dual -buried arc automatic welding automatic welding.

CO2 gas protection welding: CO2 semi -automatic welding, CO2 semi -automatic pad single -sided welding, CO2 automatic angle welding, gas vertical vertical welding, multi -layer gas vertical automatic welding, double wire single -sided MAG welding, mig, tig

Electric slag welding: melting mouth electric residue welding

Welcome to send enquiry got more information,We are waiting for you.