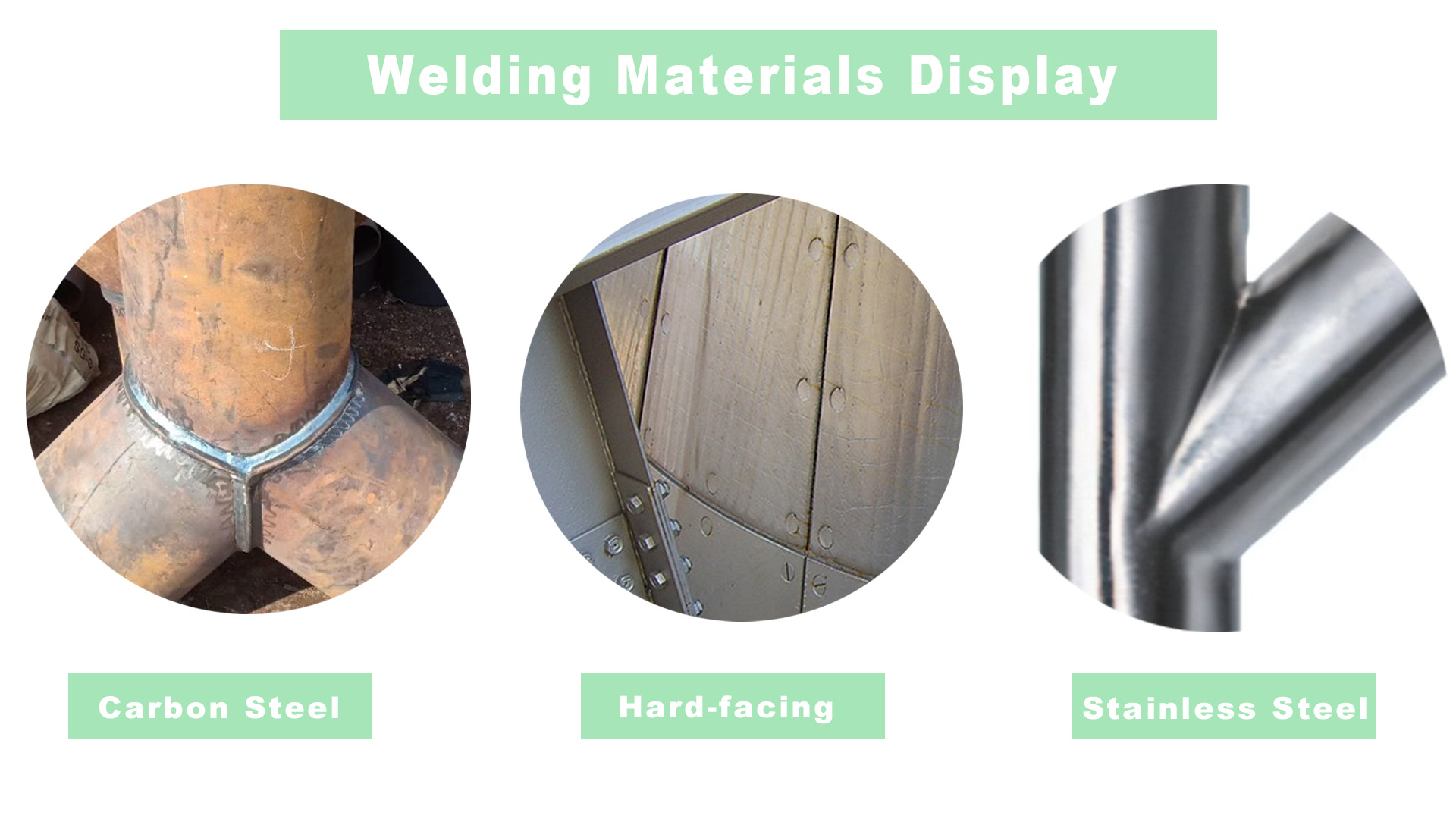

High Carbon steels TIG ER70S-2 Solid wire welding accessories

Application & Standard

1. Suitable for pipeline, pressure vessel, petrochemical and other welding applications.

2. The standard we met: GB/T39280 W 49A 3 2, AWS A5.18 ER70S-2 & A5.18M ER49S-2, ISO636-A:W 42 3 2Ti, ISO636-B:W 49A 3 2

Features

1. Due to the addition of AI,Ti, Zr and other metal elements, can be used to weld steel with rust and dirt on the surface.

2. It has excellent welding process performance, beautiful weld forming, stable mechanical properties and excellent low temperature impact performance.

Company & Factory

TYPICAL CASES

Certificates

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Ti | Zr | AL | P | S | Cu |

| GB/T RULES | 0.07 | 0.9-1.4 | 0.4-0.7 | 0.05-0.15 | 0.02-0.15 | 0.05-0.15 | 0.025 | 0.025 | 0.50 |

| AWS RULES | 0.07 | 0.9-1.4 | 0.4-0.4 | 0.05-0.15 | 0.02-0.15 | 0.05-0.15 | 0.025 | 0.025 | 0.50 |

| EXAMPLE VALUE | 0.054 | 1.070 | 0.54 | 0.08 | 0.07 | 0.06 | 0.01 | 0.005 | 0.21 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | 27/-30 | 18 | ||||

| AWS RULES | 400 | 490 | AW | 27/-30 | 22 | ||||

| EXAMPLE VALUE | 555 | 615 | AW | 175/-30 | 28 | ||||

NOTE:

H/W: horizontal position welding. O/W: over-head position welding

CERTIFICATION AUTHORITY:CWB/CE

Write your message here and send it to us