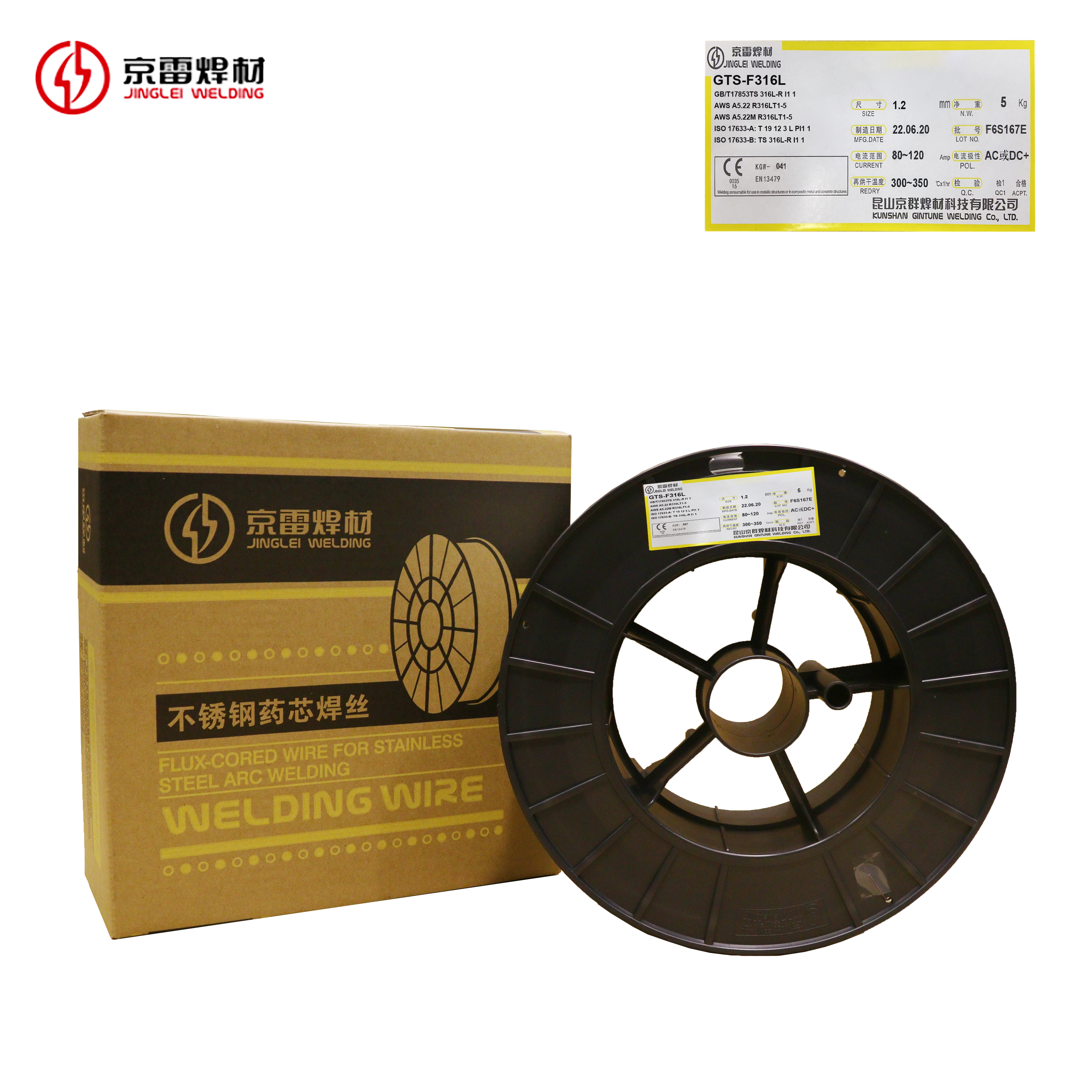

Stainless Steels Flux Cored Wire R316LT1-5 Aluminum welding material

WELDING TECHNOLOGY

Don't let the questions

Continue to haunt you

Arc instability

Unsightly molding

Excessive spatter

It is suitable for welding 18%Cr-12%Ni-2%Mo stainless steel (SUS316L, etc.) in petrochemical industry, pressure vessel, low temperature storage tank, fertilizer, urea, food machinery and other industries.

The main component is low carbon 18%Cr-12%Ni-2%Mo

Ripple fine

The back without filling up, you can get excellent weld path

The shape of the weld pass is beautiful, the slag removal is easy, and the welding process has excellent performance.

Easy slagging

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Other |

| GB/T RULES | 0.023 | 0.6 | 1.40 | 0.025 | 0.002 | 11.6 | 18.9 | 2.8 | - |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | Elongation/% | IMAPACT VALUE J/℃ | Heat treatment °C*h | |||||

| GB/T RULES | - | 654 | 35 | - | - | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | Thickness of plating(mm) | Root opening(mm) | Electricity(Amp) | |||||

| 2.2*915 | 2~4 | 2.0 | 80-100 | |||||

| 5~9 | 2.5 | 90-120 | ||||||

| ≥10 | 3.0 | 90-130 | ||||||

Factory support

The product is suitable for a

wide range of applications

WELDING TECHNOLOGY

-

Mei Jin Hua Sheng

glycol synthetic tower

-

300,000-ton Floating

Production Storage Tanker (FPSO)

Guangxi Huayi

methanol dehydrating tower

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Other |

| GB/T RULES | 0.023 | 0.6 | 1.40 | 0.025 | 0.002 | 11.6 | 18.9 | 2.8 | - |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | Elongation/% | IMAPACT VALUE J/℃ | Heat treatment °C*h | |||||

| GB/T RULES | - | 654 | 35 | - | - | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | Thickness of plating(mm) | Root opening(mm) | Electricity(Amp) | |||||

| 2.2*915 | 2~4 | 2.0 | 80-100 | |||||

| 5~9 | 2.5 | 90-120 | ||||||

| ≥10 | 3.0 | 90-130 | ||||||