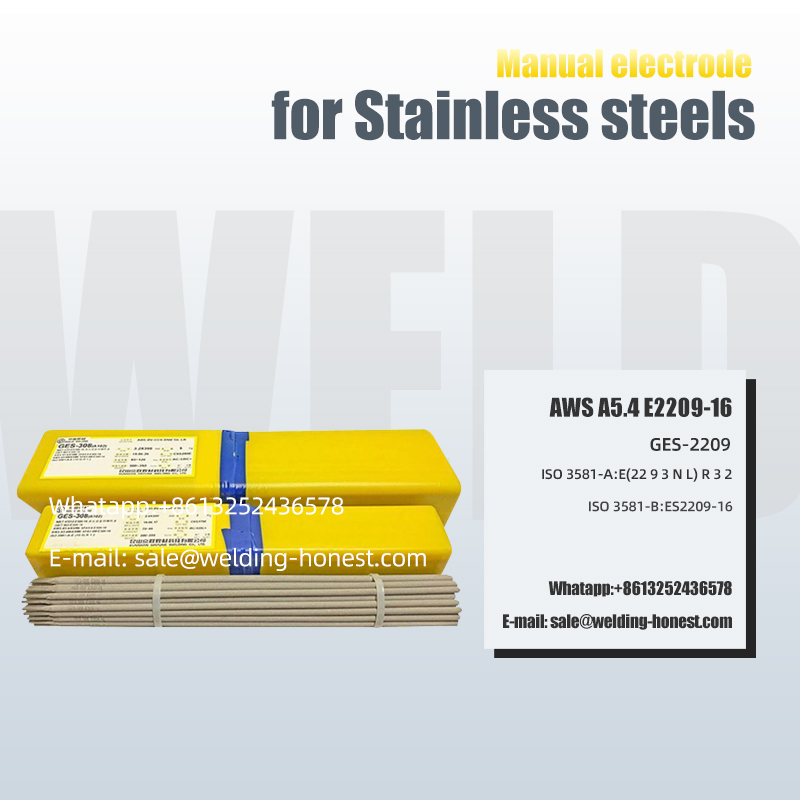

Stainless Steels Manual Electrode E2209-16 Safety injection tank Consumables

WELDING TECHNOLOGY

Don't let the questions

Continue to haunt you

Arc instability

Unsightly molding

Excessive spatter

Titanium calcium type stainless steel hand electrode

The main component is 22%Cr-9%Ni-3%Mo-N

Ripple fine

Excellent resistance to pitting and stress corrosion

Suitable for petrochemical industry

Easy slagging

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | N | |

| GB/T RULES | 0.04 | 0.5-2.0 | 1.00 | 21.5-23.5 | 7.5-10.5 | 2.5-3.5 | 0.04 | 0.03 | 0.08-0.20 | |

| AWS RULES | 0.04 | 0.5-2.0 | 1.00 | 21.5-23.5 | 8.5-10.5 | 2.5-3.5 | 0.04 | 0.03 | 0.08-0.2 | |

| EXAMPLE VALUE | 0.026 | 0.75 | 0.65 | 22.8 | 9.4 | 3.3 | 0.028 | 0.005 | 0.14 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | 690 | - | 15 | ||||

| AWS RULES | - | 690 | - | 20 | ||||

| EXAMPLE VALUE | - | 835 | 40/-40 | 26 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Factory support

The product is suitable for a

wide range of applications

WELDING TECHNOLOGY

3,000-meter deepwater semi-submersible drilling platform "Haiyang Shiyou 981"

Inner Mongolia Xinao Energy Co., LTD. 3*3000m³ low temperature spherical tank

Hengli Petrochemical 20 million tons/year refining and chemical integration project

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | N | |

| GB/T RULES | 0.04 | 0.5-2.0 | 1.00 | 21.5-23.5 | 7.5-10.5 | 2.5-3.5 | 0.04 | 0.03 | 0.08-0.20 | |

| AWS RULES | 0.04 | 0.5-2.0 | 1.00 | 21.5-23.5 | 8.5-10.5 | 2.5-3.5 | 0.04 | 0.03 | 0.08-0.2 | |

| EXAMPLE VALUE | 0.026 | 0.75 | 0.65 | 22.8 | 9.4 | 3.3 | 0.028 | 0.005 | 0.14 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | 690 | - | 15 | ||||

| AWS RULES | - | 690 | - | 20 | ||||

| EXAMPLE VALUE | - | 835 | 40/-40 | 26 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Write your message here and send it to us