Stainless steels Manual electrode E2209-16 Soldering data

Application

Applicable to the welding of the corresponding steel 00Cr22Ni5Mo3N (SUS2205) and S31803 duplex stainless steel containing 22%Cr in petrochemical industry.

Certification body:ABS、BV、CCS、DNV/GL、LR、NK、CE

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | N | |

| GB/T RULES | 0.04 | 0.5-2.0 | 1.00 | 21.5-23.5 | 7.5-10.5 | 2.5-3.5 | 0.04 | 0.03 | 0.08-0.20 | |

| AWS RULES | 0.04 | 0.5-2.0 | 1.00 | 21.5-23.5 | 8.5-10.5 | 2.5-3.5 | 0.04 | 0.03 | 0.08-0.2 | |

| EXAMPLE VALUE | 0.026 | 0.75 | 0.65 | 22.8 | 9.4 | 3.3 | 0.028 | 0.005 | 0.14 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | 690 | - | 15 | ||||

| AWS RULES | - | 690 | - | 20 | ||||

| EXAMPLE VALUE | - | 835 | 40/-40 | 26 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Titanium calcium stainless steel hand electrode with main composition of 22%Cr-9%Ni-3%Mo-N;

Molten metal contains about 40% ferrite, both austenitic and ferritic stainless steel comprehensive performance, pitting and stress corrosion resistance is excellent;

Stable arc, beautiful forming, delicate ripple, little splash, easy slag removal, good fire resistance, good porosity resistance.

Ningbo Honest Metal Materials Co,Ltd.is an international welding professional company withindependent research and development, production, sales and management. It was established in 2020.

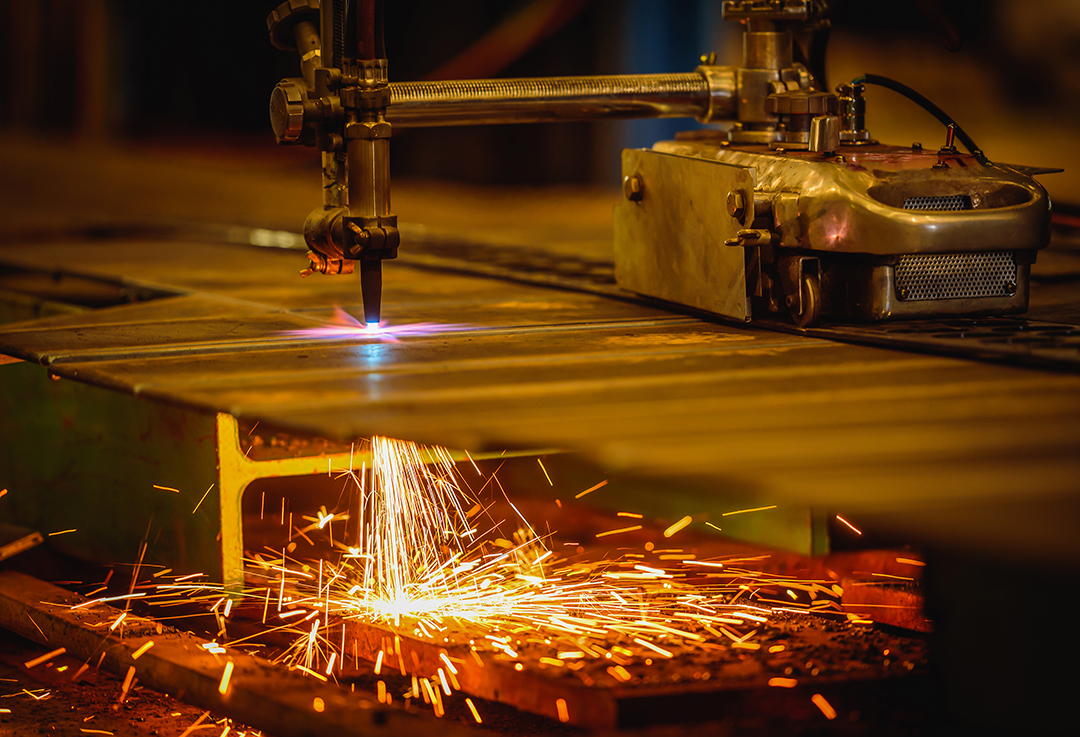

210,000 tons Newcastle type bulk carrier

Zhenhai Refinery 1 million tons/year ethylene project

Welding materials for aluminium alloys

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | N | |

| GB/T RULES | 0.04 | 0.5-2.0 | 1.00 | 21.5-23.5 | 7.5-10.5 | 2.5-3.5 | 0.04 | 0.03 | 0.08-0.20 | |

| AWS RULES | 0.04 | 0.5-2.0 | 1.00 | 21.5-23.5 | 8.5-10.5 | 2.5-3.5 | 0.04 | 0.03 | 0.08-0.2 | |

| EXAMPLE VALUE | 0.026 | 0.75 | 0.65 | 22.8 | 9.4 | 3.3 | 0.028 | 0.005 | 0.14 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | 690 | - | 15 | ||||

| AWS RULES | - | 690 | - | 20 | ||||

| EXAMPLE VALUE | - | 835 | 40/-40 | 26 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Write your message here and send it to us