Stainless steels Manual electrode E2553-16 Soldering connection

Application

Applicable to welding of 25%Cr duplex stainless steel, such as 00Cr25Ni7Mo4N, 03Cr25Ni6Mo3Cu2N, UNS 32550 (Alloy225), etc.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | N | Cu | |

| GB/T RULES | 0.06 | 0.5-1.5 | 1.00 | 24.0-27.0 | 6.5-8.5 | 2.9-3.9 | 0.04 | 0.03 | 0.10-0.25 | 1.5-2.5 | |

| AWS RULES | 0.06 | 0.5-1.5 | 1.00 | 24.0-27.0 | 6.5-8.5 | 2.9-3.9 | 0.04 | 0.03 | 0.10-0.25 | 1.5-2.5 | |

| EXAMPLE VALUE | 0.042 | 1.1 | 0.35 | 25.1 | 7.9 | 3.1 | 0.015 | 0.007 | 0.18 | 1.7 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | 760 | - | 13 | ||||

| AWS RULES | - | 760 | - | 15 | ||||

| EXAMPLE VALUE | - | 900 | - | 22 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

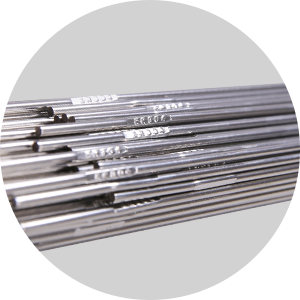

Titanium calcium stainless steel hand electrode, the main composition of 25%Cr-7%Ni-3%Mo-N;

High strength and good resistance to pitting corrosion and stress corrosion cracking;

Stable arc, beautiful forming, delicate ripple, little splash, easy slag removal, good fire resistance, good porosity resistance.

Ningbo Honest Metal Materials Co,Ltd.is an international welding professional company withindependent research and development, production, sales and management. It was established in 2020.

300,000-ton super large crude oil tanker

Arctic LNG-2 project

Tangshan LNG external transportation pipeline Project

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | N | Cu | |

| GB/T RULES | 0.06 | 0.5-1.5 | 1.00 | 24.0-27.0 | 6.5-8.5 | 2.9-3.9 | 0.04 | 0.03 | 0.10-0.25 | 1.5-2.5 | |

| AWS RULES | 0.06 | 0.5-1.5 | 1.00 | 24.0-27.0 | 6.5-8.5 | 2.9-3.9 | 0.04 | 0.03 | 0.10-0.25 | 1.5-2.5 | |

| EXAMPLE VALUE | 0.042 | 1.1 | 0.35 | 25.1 | 7.9 | 3.1 | 0.015 | 0.007 | 0.18 | 1.7 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | 760 | - | 13 | ||||

| AWS RULES | - | 760 | - | 15 | ||||

| EXAMPLE VALUE | - | 900 | - | 22 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Write your message here and send it to us