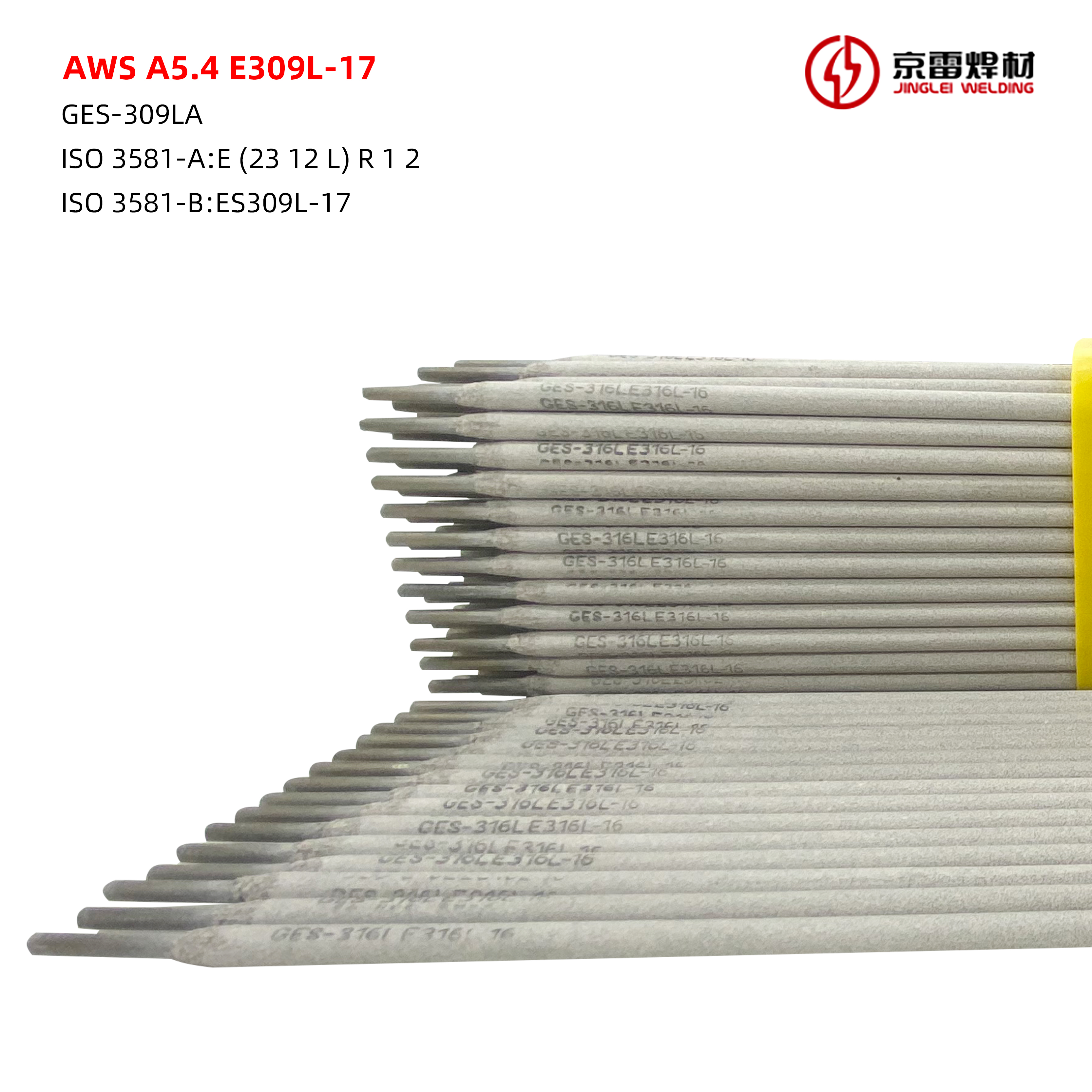

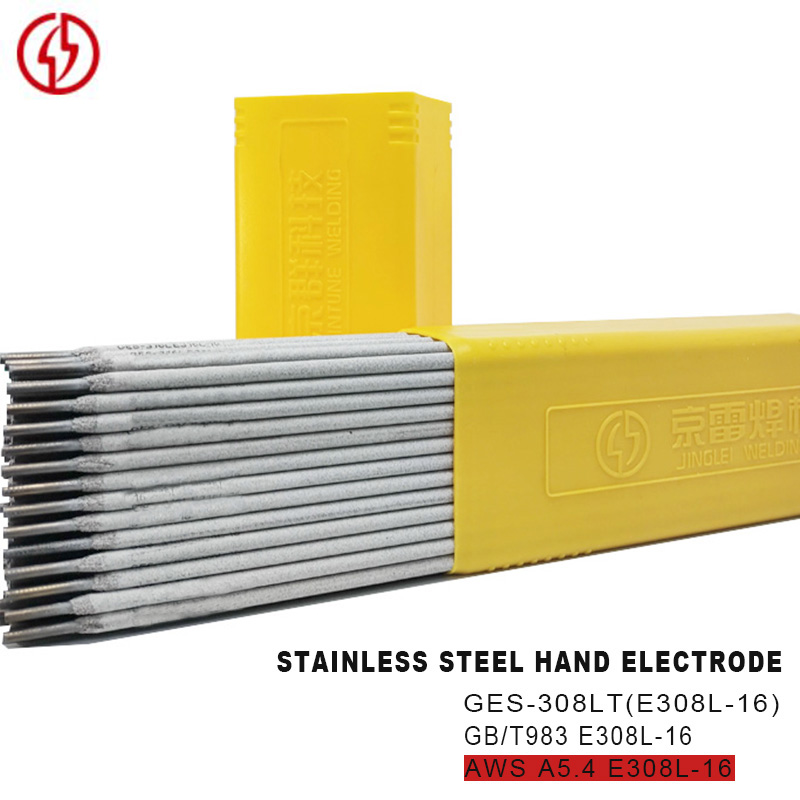

Stainless Steels Manual Electrode E309L-17 VLCC ship crude oil soldering

WELDING TECHNOLOGY

Don't let the questions

Continue to haunt you

Arc instability

Unsightly molding

Excessive spatter

Suitable for stainless steel and carbon steel welding,

petrochemical industry reactor inner wall surfacing transition metal;

Or used in poor toughness of martensite, ferritic stainless steel welding.

Ripple fine

Acid type stainless steel hand electrode, jet arc,

the main component is low C-22%Cr-12%Ni, excellent cracking resistance

Good welding operation, stable arc, beautiful forming, delicate ripple, little splash, easy slag removal;

The coating has good fire resistance, good porosity resistance,

stable mechanical properties of molten metal, and high X-Ray pass rate.

Easy slagging

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Other |

| GB/T RULES | 0.034 | 0.71 | 0.98 | 0.022 | 0.003 | 13.73 | 24.8 | 0.18 | 0.09 | - |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | Heat treatment °C*h | ||||

| GB/T RULES | 600 | 37 | - | - | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Factory support

The product is suitable for a

wide range of applications

WELDING TECHNOLOGY

-

Jiangsu Donghua Energy

80,000 m3 propane storage tank

Zhangjiagang Hanzhong Cryogenic

Technology Co.,LTD. Cryogenic storage

and transportation container

-

Tangshan LNG export pipeline project

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Other |

| GB/T RULES | 0.034 | 0.71 | 0.98 | 0.022 | 0.003 | 13.73 | 24.8 | 0.18 | 0.09 | - |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | Heat treatment °C*h | ||||

| GB/T RULES | 600 | 37 | - | - | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||