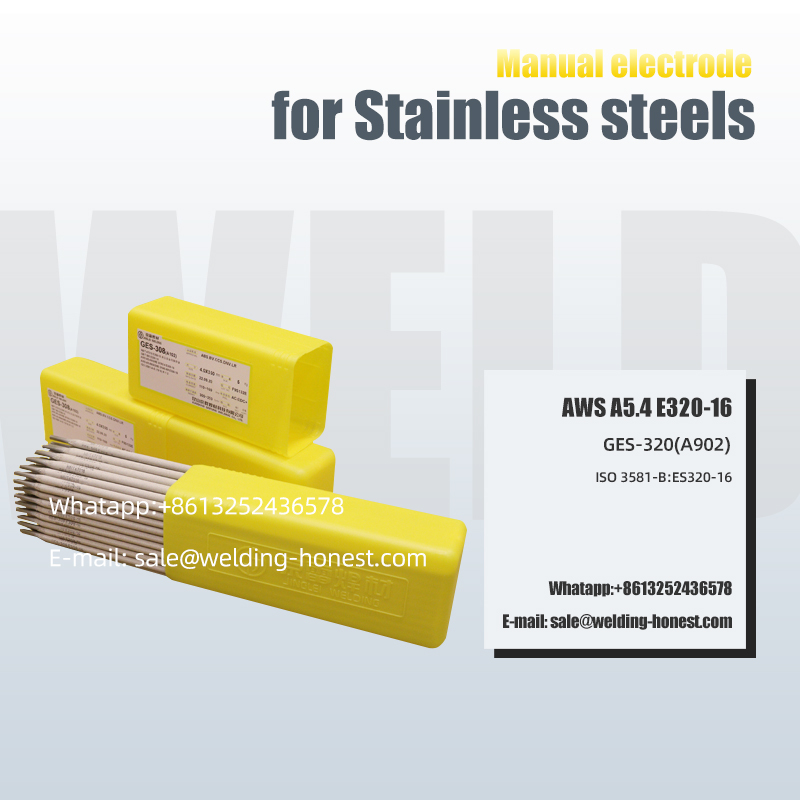

Stainless Steels Manual Electrode E312-17 ore boat weld

WELDING TECHNOLOGY

Don't let the questions

Continue to haunt you

Arc instability

Unsightly molding

Excessive spatter

It is suitable for all kinds of hard iron material and hardening

alloy steel which are difficult to weld and easy to crack or have porosity

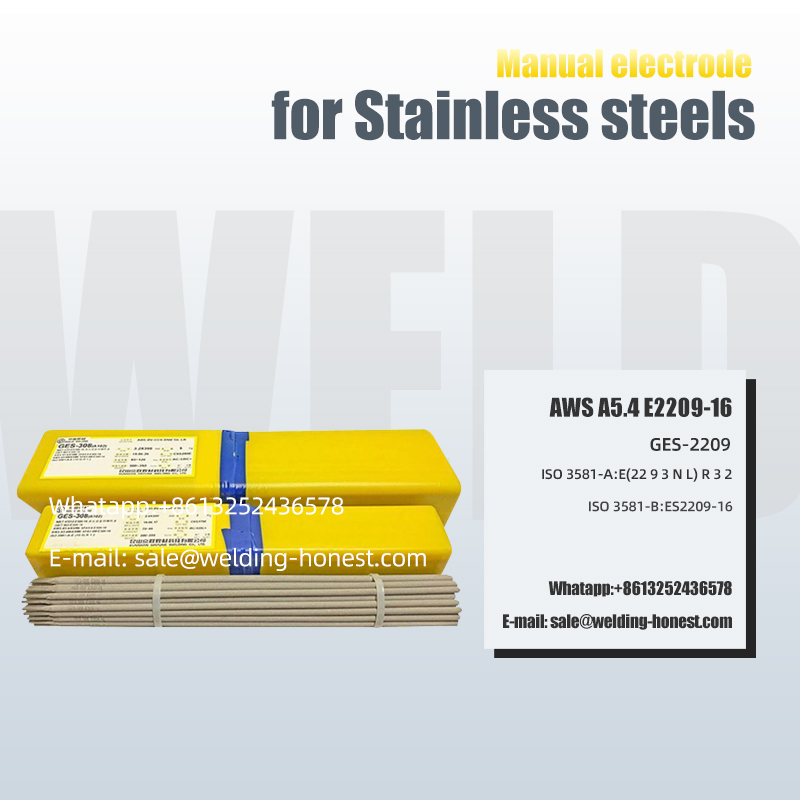

Acid type two-phase stainless steel hand electrode, jet arc,

the main component is 29%Cr-9%Ni, commonly known as "universal electrode.

Ripple fine

Good welding operation, stable arc, beautiful forming,

delicate ripple, little splash, easy slag removal.

The coating has good fire resistance, good porosity resistance, and stable mechanical properties of fused metal

Easy slagging

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Other |

| GB/T RULES | 0.057 | 1.1 | 0.74 | 0.026 | 0.005 | 9.8 | 28.4 | 0.07 | 0.11 | - |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | Heat treatment °C*h | ||||

| GB/T RULES | 800 | 25 | - | - | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

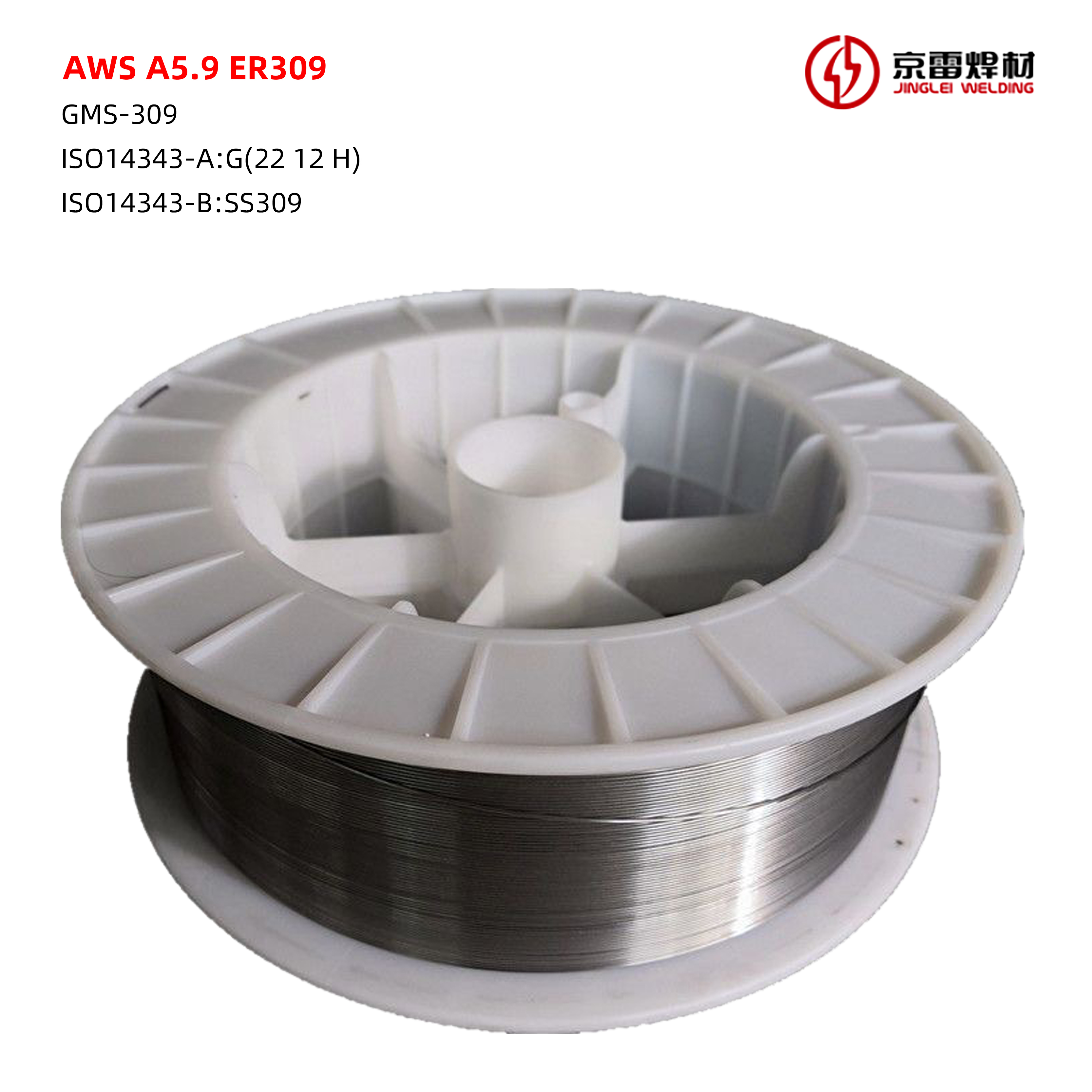

Factory support

The product is suitable for a

wide range of applications

WELDING TECHNOLOGY

-

2.3 million barrels of

SBM Fast4ward FPSO

-

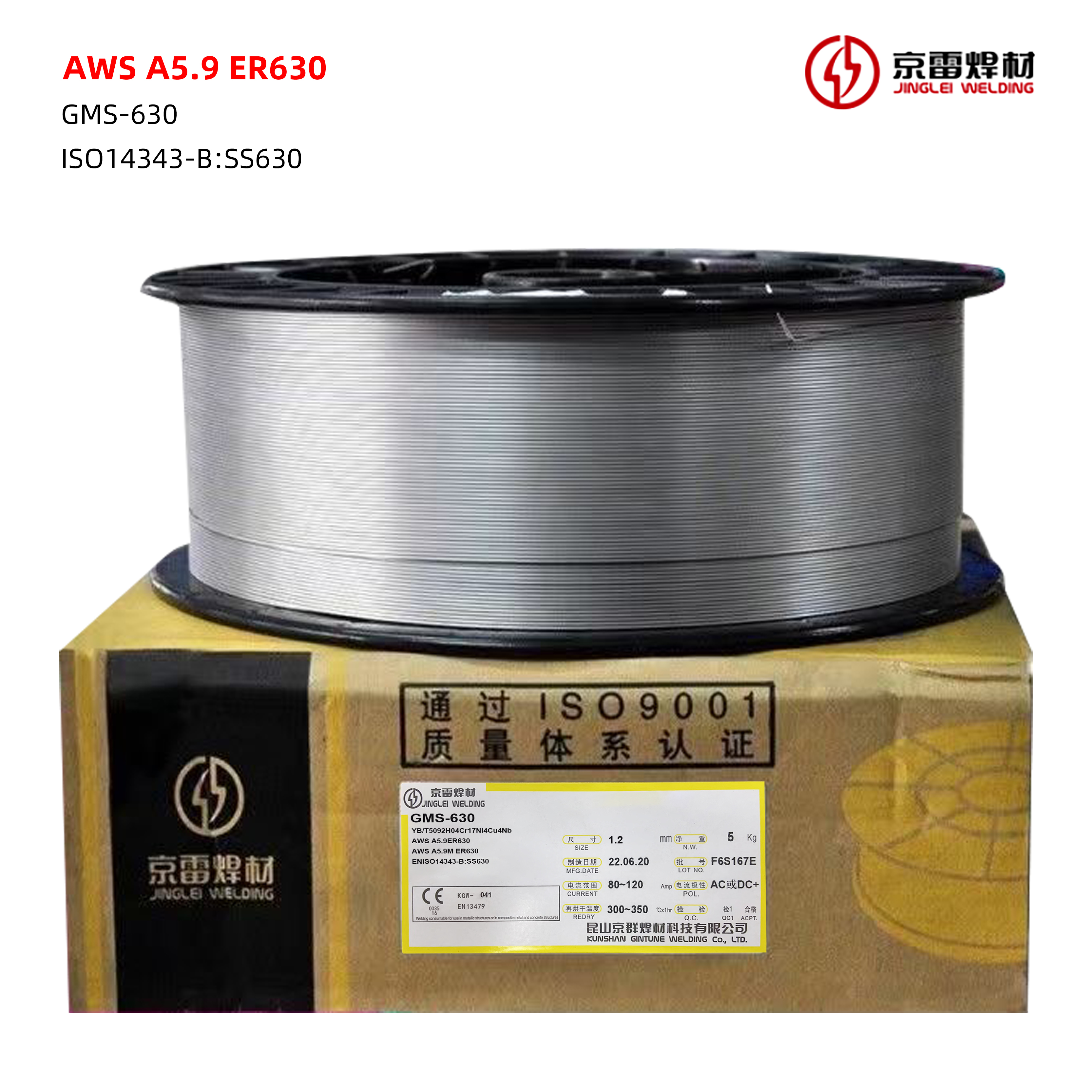

GDS-2209/GXS-E330

tube surfacing site

Hainan Huasheng

phenol recovery tower

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Other |

| GB/T RULES | 0.057 | 1.1 | 0.74 | 0.026 | 0.005 | 9.8 | 28.4 | 0.07 | 0.11 | - |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | Heat treatment °C*h | ||||

| GB/T RULES | 800 | 25 | - | - | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||