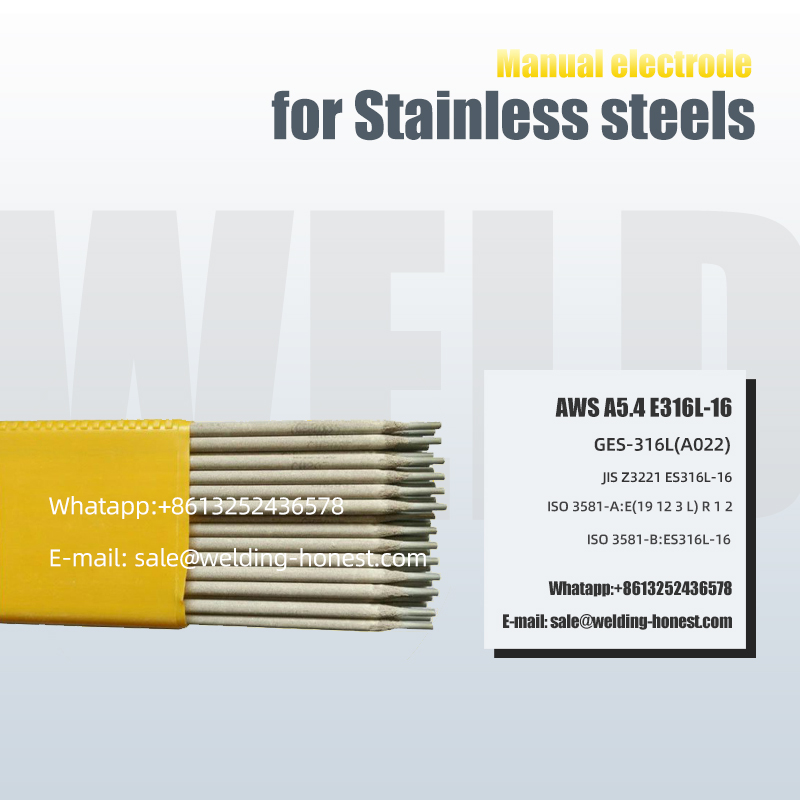

Stainless Steels Manual Electrode E316L-16 cargo ship welding wire coil

WELDING TECHNOLOGY

Don't let the questions

Continue to haunt you

Arc instability

Unsightly molding

Excessive spatter

Titanium calcium type stainless steel hand electrode

The main component is low carbon -18%Cr-12%Ni-2%Mo

Ripple fine

Wide range of application

Pitting corrosion resistance, excellent seawater corrosion performance

Easy slagging

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.04 | 0.5-2.5 | 1.00 | 17.0-20.0 | 11.0-14.0 | 2.0-3.0 | 0.04 | 0.03 | 0.75 |

| AWS RULES | 0.04 | 0.5-2.5 | 1.00 | 17.0-20.0 | 11.0-14.0 | 2.0-3.0 | 0.04 | 0.03 | 0.75 |

| EXAMPLE VALUE | 0.028 | 0.095 | 0.75 | 18.8 | 11.6 | 2.4 | 0.027 | 0.003 | 0.05 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | - | 490 | - | - | 25 | |||||

| AWS RULES | - | 490 | - | - | 30 | |||||

| EXAMPLE VALUE | - | 575 | - | - | 39 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | ||||||

Factory support

The product is suitable for a

wide range of applications

WELDING TECHNOLOGY

37 ,000 TON

GENERAL CARGO SHIP

37 ,000 TON

GENERAL CARGO SHIP

37 ,000 TON

GENERAL CARGO SHIP

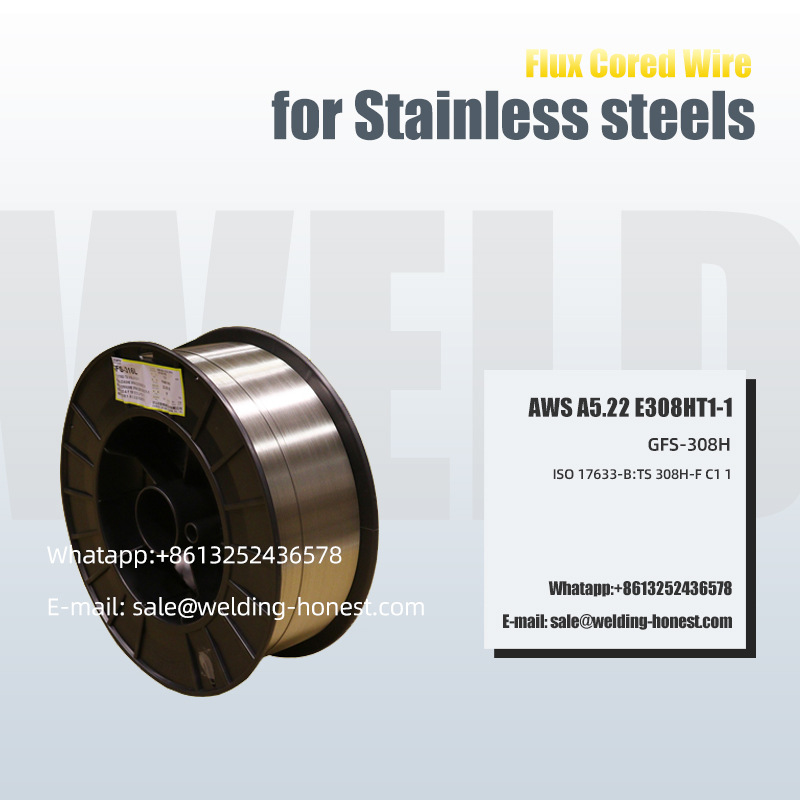

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.04 | 0.5-2.5 | 1.00 | 17.0-20.0 | 11.0-14.0 | 2.0-3.0 | 0.04 | 0.03 | 0.75 |

| AWS RULES | 0.04 | 0.5-2.5 | 1.00 | 17.0-20.0 | 11.0-14.0 | 2.0-3.0 | 0.04 | 0.03 | 0.75 |

| EXAMPLE VALUE | 0.028 | 0.095 | 0.75 | 18.8 | 11.6 | 2.4 | 0.027 | 0.003 | 0.05 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | - | 490 | - | - | 25 | |||||

| AWS RULES | - | 490 | - | - | 30 | |||||

| EXAMPLE VALUE | - | 575 | - | - | 39 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | ||||||

Write your message here and send it to us