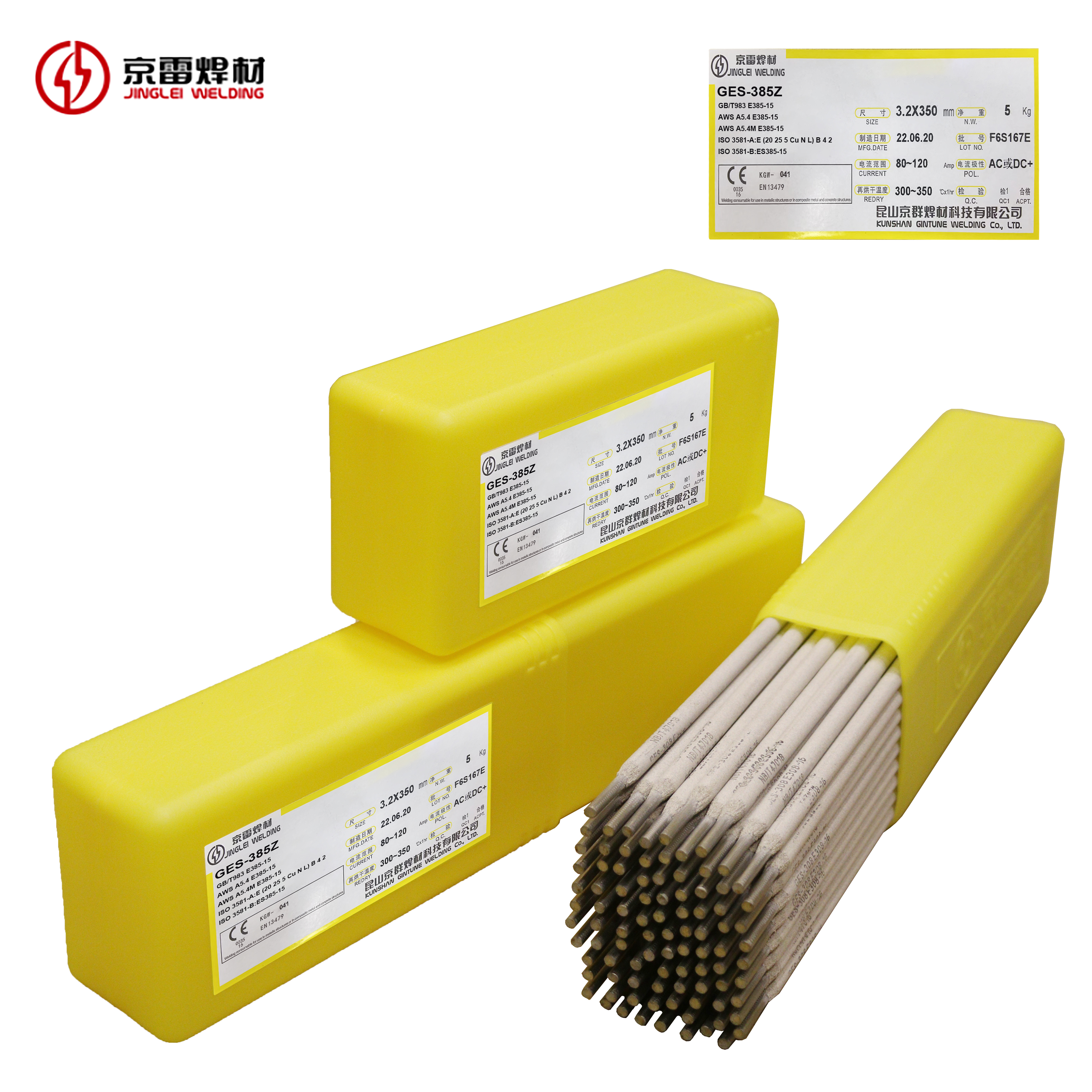

Stainless Steels Manual Electrode E385-15 Cryogenic storage vessel welding materials

WELDING TECHNOLOGY

Don't let the questions

Continue to haunt you

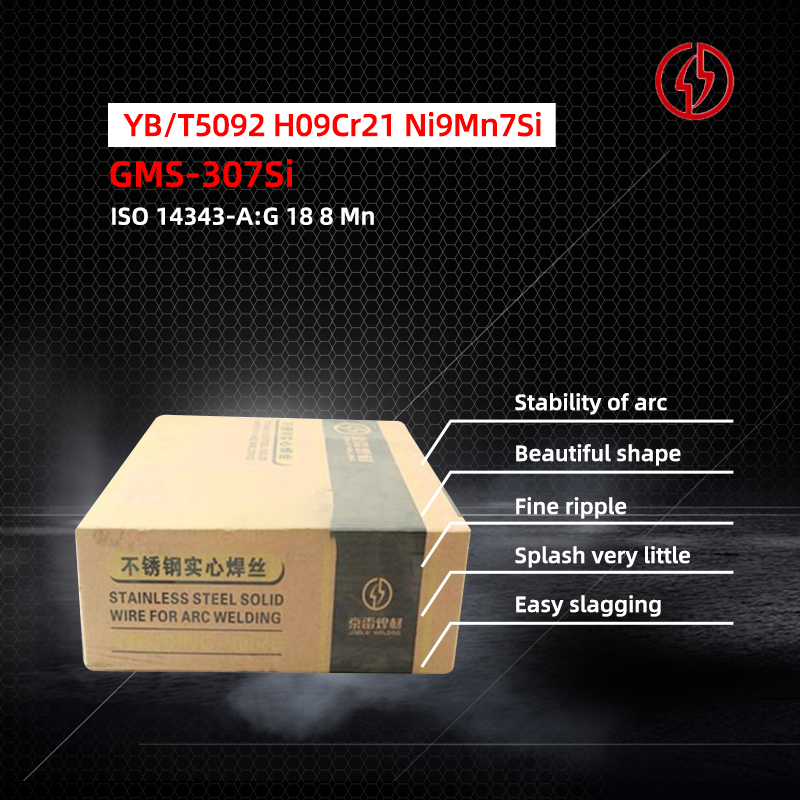

Arc instability

Unsightly molding

Excessive spatter

Often used in a variety of strong acid tower, tank, pipeline and storage container, such as 904L welding.

Low hydrogen pure austenitic stainless steel hand electrode, the main composition is low C-20%Cr-25%Ni-5%Mo-2%Cu.

Ripple fine

Excellent corrosion resistance, can resist sulfuric acid,

Phosphoric acid uniform corrosion, under atmospheric pressure resistance to any temperature any

concentration acetic acid corrosion, can effectively solve the halide pitting corrosion, slot corrosion,

stress corrosion and other problems; Excellent welding performance, excellent fire resistance,

good porosity resistance, stable mechanical properties of molten metal.

Easy slagging

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Other |

| GB/T RULES | 0.031 | 2.27 | 0.66 | 0.019 | 0.003 | 25.5 | 21.1 | 5.15 | 1.68 | - |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | Heat treatment °C*h | ||||

| GB/T RULES | 615 | 38 | - | - | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Factory support

The product is suitable for a

wide range of applications

WELDING TECHNOLOGY

-

Welding materials for silencers

-

Sanmen Nuclear Power

-

180,000 tons Capesize bulk carrier

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Other |

| GB/T RULES | 0.031 | 2.27 | 0.66 | 0.019 | 0.003 | 25.5 | 21.1 | 5.15 | 1.68 | - |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | Heat treatment °C*h | ||||

| GB/T RULES | 615 | 38 | - | - | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||