Stainless steels Manual electrode E385-16 weld fabrication connection

Application

Suitable for all kinds of strong acid tower, tank, pipeline and storage and transportation container welding, such as 904L.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T RULES | 0.03 | 1.0-2.5 | 0.90 | 19.5-21.5 | 24.0-26.0 | 4.2-5.2 | 0.03 | 0.02 | 1.2-2.0 | |

| AWS RULES | 0.03 | 1.0-2.5 | 0.90 | 19.5-21.5 | 24.0-26.0 | 4.2-5.2 | 0.03 | 0.02 | 1.2-2.0 | |

| EXAMPLE VALUE | 0.028 | 1.35 | 0.58 | 20.5 | 25 | 4.85 | 0.02 | 0.001 | 1.70 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | 520 | - | 28 | ||||

| AWS RULES | - | 520 | - | 30 | ||||

| EXAMPLE VALUE | - | 600 | - | 37 | ||||

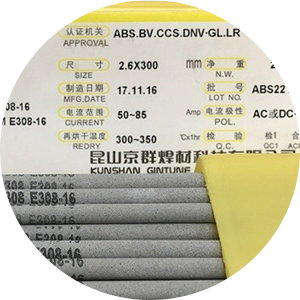

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Titanium calcium stainless steel hand electrode, the main composition is 20%Cr-25%Ni-5%Mo-2%Cu;

Can resist sulfuric acid, phosphoric acid corrosion; It can resist the corrosion of acetic acid at any temperature and at any concentration under normal pressure. It can effectively solve the problems of pore corrosion, pitting corrosion, crevice corrosion and stress corrosion of halide.

Stable arc, beautiful forming, delicate ripple, little splash, easy slag removal, good fire resistance, good porosity resistance.

Ningbo Honest Metal Materials Co,Ltd.is an international welding professional company withindependent research and development, production, sales and management. It was established in 2020.

37,000 tons general cargo ship

Shaanxi Pucheng -50℃ propane spherical tank project

Welding materials for railway vehicles

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T RULES | 0.03 | 1.0-2.5 | 0.90 | 19.5-21.5 | 24.0-26.0 | 4.2-5.2 | 0.03 | 0.02 | 1.2-2.0 | |

| AWS RULES | 0.03 | 1.0-2.5 | 0.90 | 19.5-21.5 | 24.0-26.0 | 4.2-5.2 | 0.03 | 0.02 | 1.2-2.0 | |

| EXAMPLE VALUE | 0.028 | 1.35 | 0.58 | 20.5 | 25 | 4.85 | 0.02 | 0.001 | 1.70 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | 520 | - | 28 | ||||

| AWS RULES | - | 520 | - | 30 | ||||

| EXAMPLE VALUE | - | 600 | - | 37 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||