Stainless steels MIG ER2209 Welding stuff

Application

It is suitable for welding of 00Cr22Ni5Mo3N(SUS2205) and S31803 duplex stainless steel containing 22%Cr in petrochemical industry.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T RULES | 0.03 | 0.5-2.0 | 0.90 | 21.5-23.5 | 7.5-9.5 | 2.5-3.5 | 0.03 | 0.03 | 0.75 | |

| AWS RULES | 0.03 | 0.5-2.0 | 0.90 | 21.5-23.5 | 7.5-9.5 | 2.5-3.5 | 0.03 | 0.03 | 0.75 | |

| EXAMPLE VALUE | 0.016 | 1.85 | 0.51 | 22.59 | 8.72 | 3.02 | 0.023 | 0.012 | 0.1 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | FN | ||||

| GB/T RULES | - | - | - | - | - | ||||

| AWS RULES | - | - | - | - | - | ||||

| EXAMPLE VALUE | - | 795 | 95/-40 | 33 | 37 | ||||

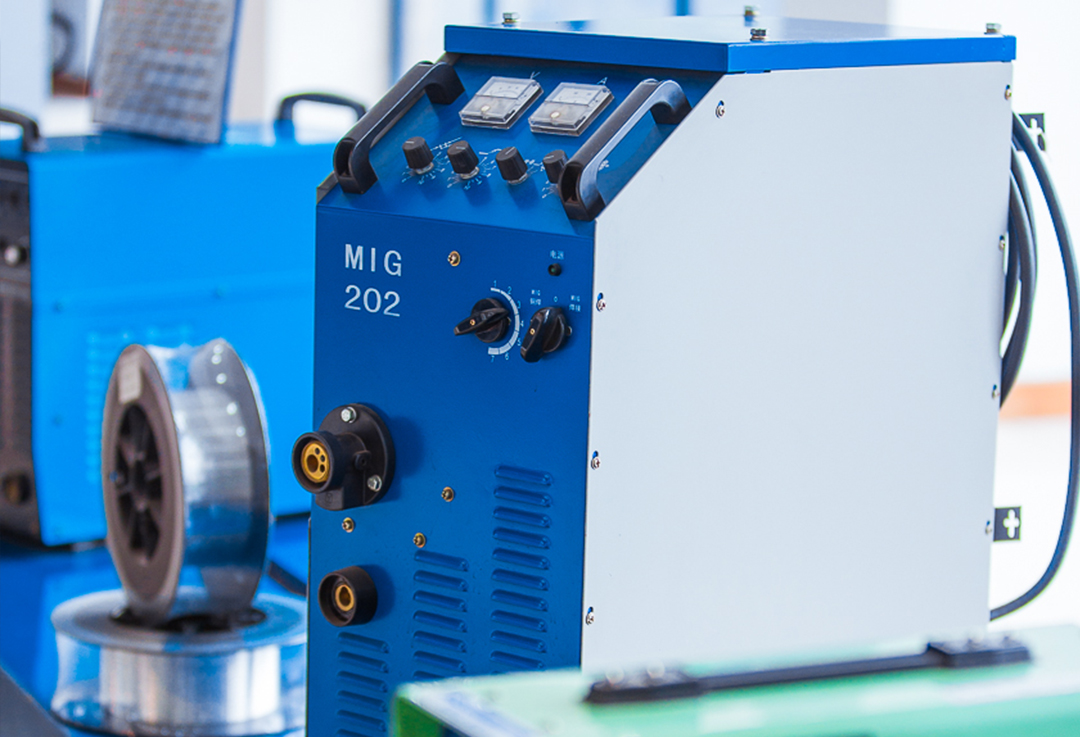

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 0.8 | 1.0 | 1.2 | ||||

| ELECTRICITY (Amp) |

H/W | 70-150 | 100-200 | 140-220 | |||

| O/W | 50-120 | 80-150 | 120-180 | ||||

Peculiarity

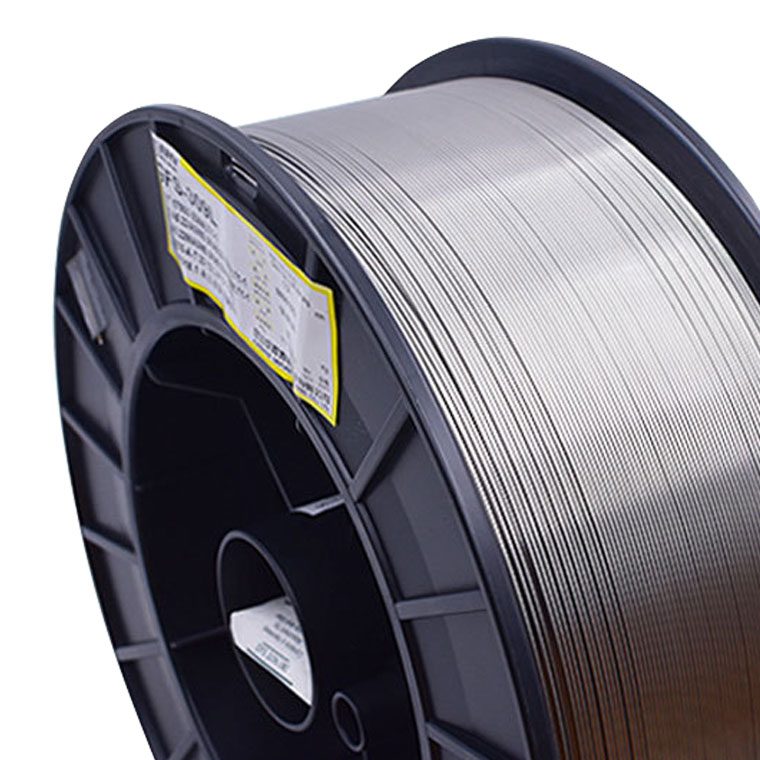

The main component is 22%Cr-9%Ni-3%Mo-N.

Molten metal contains about 40% ferrite, both austenitic and ferritic stainless steel comprehensive performance, pitting and stress corrosion resistance is excellent.

Smooth wire feeding, stable arc, beautiful forming, good flow of molten iron, less splash, with excellent welding process performance.

Show details

Stability of arc

Beautiful shape

About us

Factory fioor display

Application case

85000 m3 Very Large ethane Ethylene Carrier (VLEC)

Thermal power application

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T RULES | 0.03 | 0.5-2.0 | 0.90 | 21.5-23.5 | 7.5-9.5 | 2.5-3.5 | 0.03 | 0.03 | 0.75 | |

| AWS RULES | 0.03 | 0.5-2.0 | 0.90 | 21.5-23.5 | 7.5-9.5 | 2.5-3.5 | 0.03 | 0.03 | 0.75 | |

| EXAMPLE VALUE | 0.016 | 1.85 | 0.51 | 22.59 | 8.72 | 3.02 | 0.023 | 0.012 | 0.1 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | FN | ||||

| GB/T RULES | - | - | - | - | - | ||||

| AWS RULES | - | - | - | - | - | ||||

| EXAMPLE VALUE | - | 795 | 95/-40 | 33 | 37 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 0.8 | 1.0 | 1.2 | ||||

| ELECTRICITY (Amp) |

H/W | 70-150 | 100-200 | 140-220 | |||

| O/W | 50-120 | 80-150 | 120-180 | ||||

Write your message here and send it to us