Stainless steels MIG ER410NiMo Mod Welding accessories

Application

It is often used in wear-resistant and corrosion-resistant occasions such as hydropower station and valves, such as ASTM CA6NM castings or similar materials, small size 410, 410S, 405 base materials and so on.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T RULES | - | - | - | - | - | - | - | - | - | |

| AWS RULES | - | - | - | - | - | - | - | - | - | |

| EXAMPLE VALUE | 0.013 | 0.89 | 0.6 | 12.4 | 4.8 | 0.56 | 0.016 | 0.001 | 0.01 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | - | - | - | ||||

| AWS RULES | - | - | - | - | ||||

| EXAMPLE VALUE | 712 | 855 | 78/0 | 21 | ||||

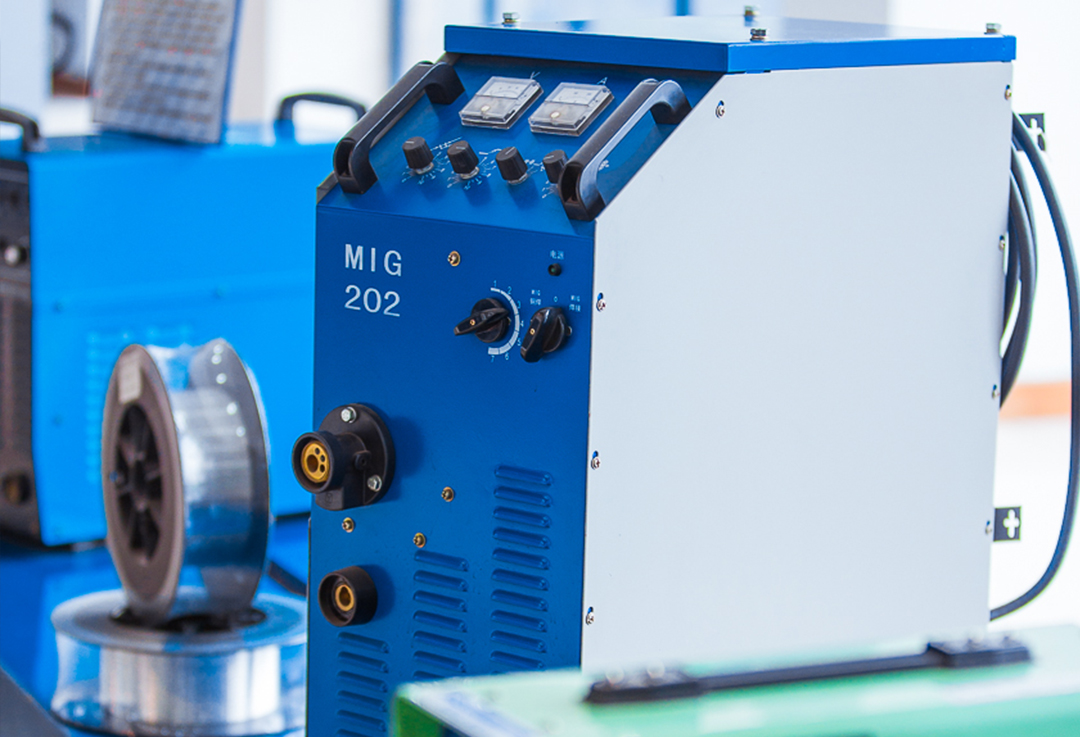

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 0.8 | 1.0 | 1.2 | ||||

| ELECTRICITY (Amp) |

H/W | 70-150 | 100-200 | 140-220 | |||

| O/W | 50-120 | 80-150 | 120-180 | ||||

Peculiarity

Due to the addition of Ni and Mo, its strength and hardness are higher than 410.

Used for more demanding wear and corrosion resistance occasions.

Smooth wire feeding, stable arc, beautiful forming, less splash, with excellent welding process performance.

Show details

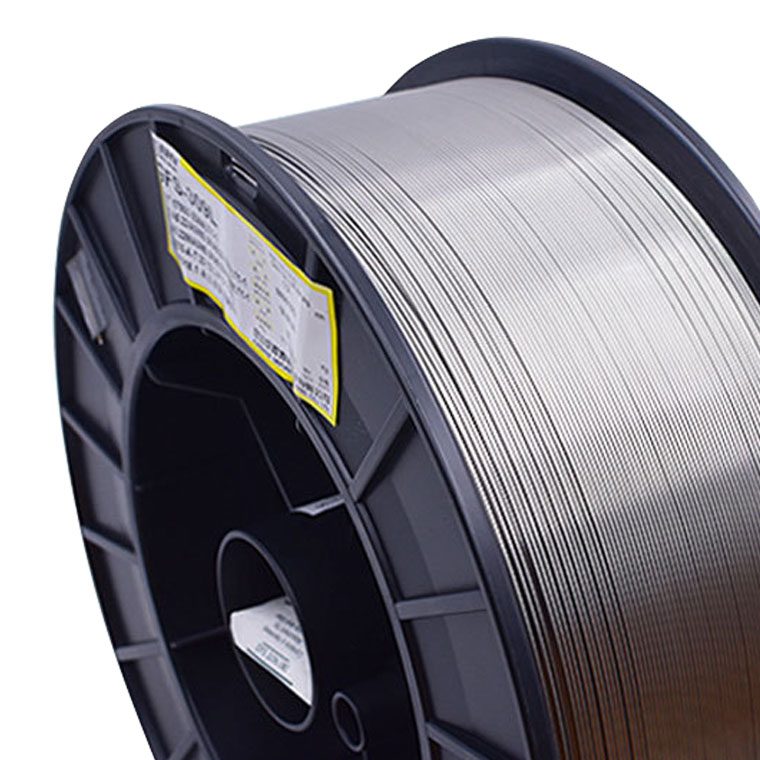

Beautiful shape

Beautiful shape

About us

Factory fioor display

Application case

Tianshu Xing, a large liquefied natural gas (LNG) carrier with 174,000 cubic meters, was built as a bow

981 semi-submersible drilling rig

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T RULES | - | - | - | - | - | - | - | - | - | |

| AWS RULES | - | - | - | - | - | - | - | - | - | |

| EXAMPLE VALUE | 0.013 | 0.89 | 0.6 | 12.4 | 4.8 | 0.56 | 0.016 | 0.001 | 0.01 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | - | - | - | ||||

| AWS RULES | - | - | - | - | ||||

| EXAMPLE VALUE | 712 | 855 | 78/0 | 21 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 0.8 | 1.0 | 1.2 | ||||

| ELECTRICITY (Amp) |

H/W | 70-150 | 100-200 | 140-220 | |||

| O/W | 50-120 | 80-150 | 120-180 | ||||

Write your message here and send it to us