Have Six types for stainless steel

Manual electrodes: 16 Titanium calcium,15 basic type,17Titanic acid ,argon arc welding

Flux cored wire:CO2 protech, Mix gas protect,No BI, All position,Low Temp, argon arc welding

Solid wire:Gas protect and GTAW

SAW wire:Solid style

Metal Cored wire: Gas protect and SAW

Welding strip: Austenitic, dual-phase and hard surface wear-resistant, single-layer electroslag surfacing

Stainless steels

-

Stainless steels Flux cored wire E307T1-4 metal Jointing materials

GB/T17853 TS307-F M21 1

AWS A5.4 E307T1-4

AWS A5.22M E307T1-4

Whatapp:+8613252436578

E-mail: sale@welding-honest.com

-

Stainless steels MIG ER308 metal Jointing materials

YB/T5092 H06Cr21Ni10

AWS A5.9 ER308

Whatapp:+8613252436578

E-mail: sale@welding-honest.com

-

Stainless steels TIG ER308 metal Jointing materials

YB/T5092 H06Cr21Ni10

AWS A5.9 ER308

Whatapp:+8613252436578

E-mail: sale@welding-honest.com

-

Stainless steels Metal cored wire EC308L metal Jointing stuff

GB/T17853 TS 308L-M M21 0

AWS A5.22 EC308L

AWS A5.22M EC308L

Whatapp:+8613252436578

E-mail: sale@welding-honest.com

-

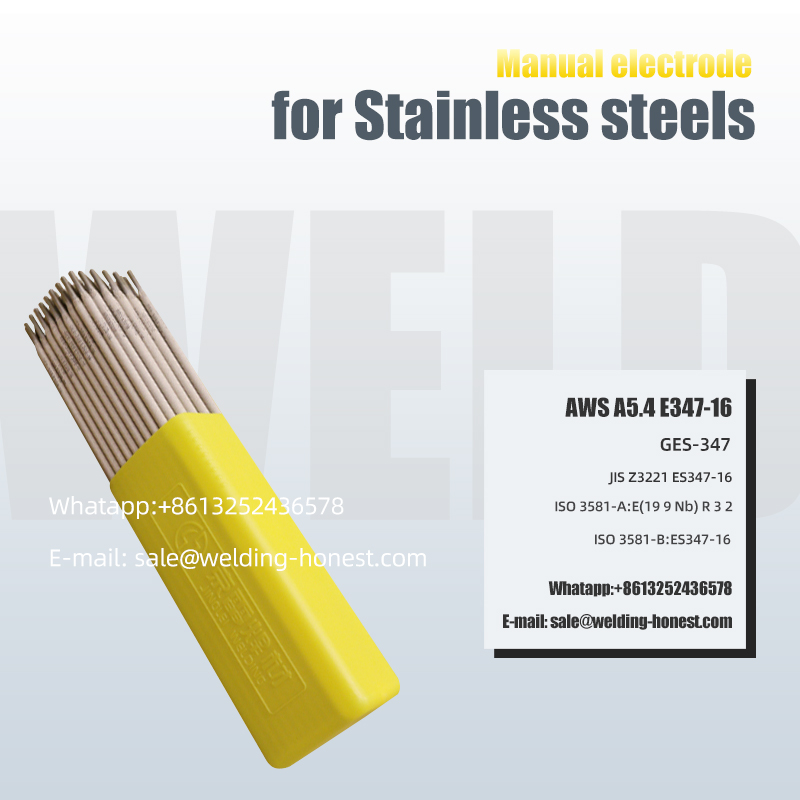

Stainless Steels Manual Electrode E347-16 liquefied natural gas carrier electrode

GB/T983 E347-16

AWS A5.4 E347-16

JIS Z3221 ES347-16

ISO 3581-A:E(19 9 Nb) R 3 2

ISO 3581-B:ES347-16

Whatapp:+8613252436578

E-mail: sale@welding-honest.com

-

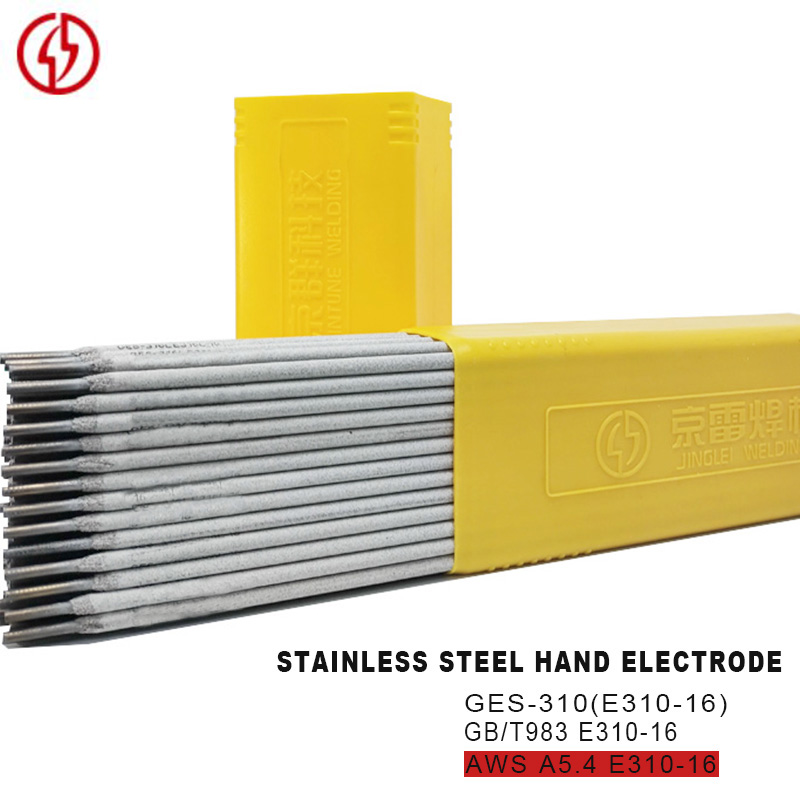

AWS E310-16 Stainless steels Manual electrode weld fabrication connection

Titanium calcium type Cr26Ni21 austenitic stainless steel electrode, molten metal at 900-1100℃ high temperature conditions has excellent oxidation resistance, AC and DC dual use. Good welding technology. The same type of heat resistant stainless steel is used for working at high temperature. It is also used for welding large hardened chromium steels [such as Cr5Mo, Cr9Mo, Cr13, Cr28, etc.] and dissimilar steel.

-

Stainless steels Manual electrode E2209-16 Soldering data

GB/T983 E2209-16

AWS A5.4 E2209-16

A5.4M E2209-16

ISO 3581-A:E(22 9 3 N L)R 3 2

ISO 3581-B:ES2209-16

Whatapp:+8613252436578

E-mail: sale@welding-honest.com

-

Stainless steels Manual electrode E347L-16 weld fabrication data

GB/T983 E347L-16

AWS A5.4 E347-16

A5.4M E347-16

JIS Z3221 ES347L-16

ISO 3581-B:ES347L-16

Whatapp:+8613252436578

E-mail: sale@welding-honest.com

-

Stainless steels EC409 SAW welding wire and flux Welding stuff

Uses: 1. Suitable for automobile exhaust system and automobile muffler welding.

Characteristics: 1. The weld metal contains an appropriate amount of Ti element, so that it has good oxidation resistance and corrosion resistance. 2 The arc is soft and stable, less spatter, beautiful forming, almost no slag, stable wire feeding, and excellent welding process performance.

-

AWS E309MoL Stainless steels Manual electrode weld fabrication data

It is mainly used for welding 316 type composite steel or surfacing on carbon steel. Low carbon content is to reduce the possibility of intergranular corrosion. As for the addition of Mo element is to match the base metal, its role is to strengthen the ferrite, improve the strength and hardness of steel; 2, reduce the critical cooling rate of steel, improve the hardenability of steel; 3, improve the heat resistance and high temperature strength of steel.

-

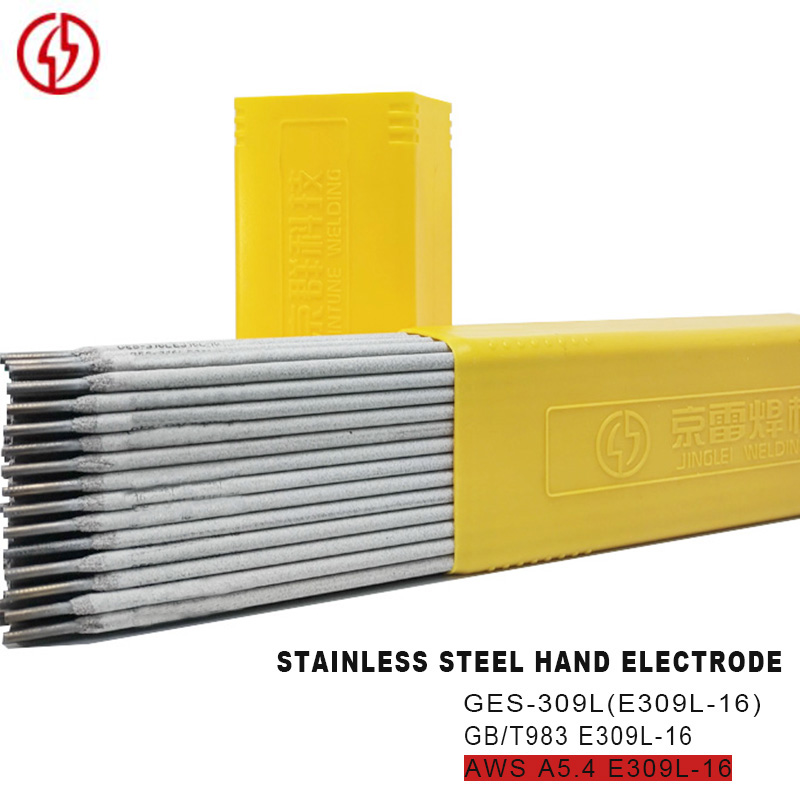

AWS E309L-16 Stainless steels Manual electrode weld fabrication jointing

E309L-16 is Cr23Ni13 stainless steel electrode with titanium calcium coating. The coated metal has good cracking resistance and oxidation resistance. Ac-dc dual use, good operation process performance. In order to improve the crack resistance and corrosion resistance of the fused metal, the Mo content is appropriately increased, which is about 1% higher than that in GB/T983-1995 E309L-16.

-

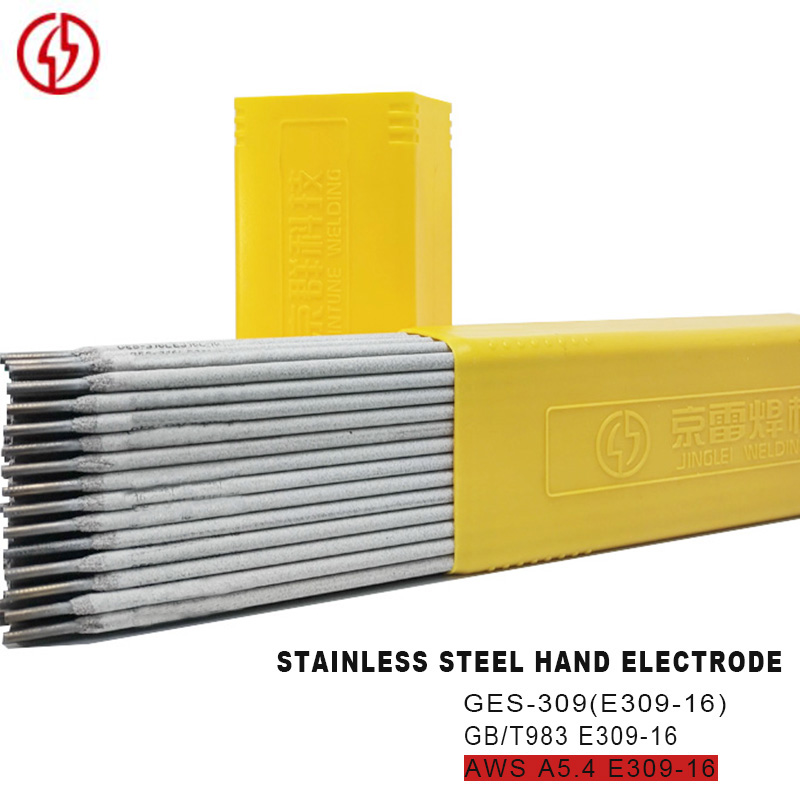

AWS E309-16 Stainless steels Solid wire Welding materials

It is suitable for welding the same type of stainless steel structure, composite steel and dissimilar steel components made by synthetic fiber, petrochemical equipment, etc. It can also be used for surfacing of transition layer of inner wall of pressure equipment of nuclear reactor and welding of structure inside tower.