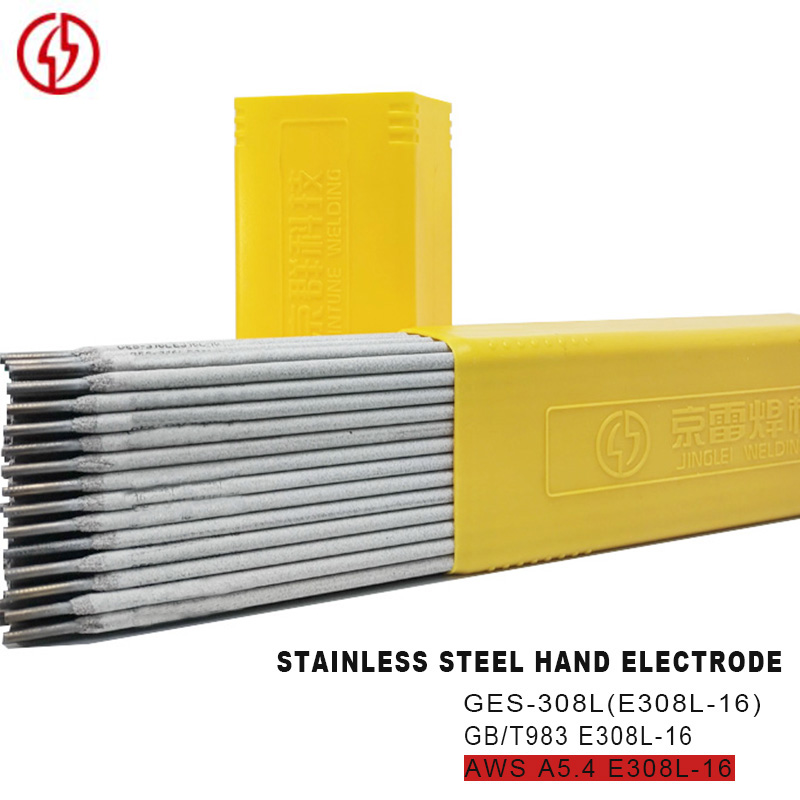

Well-designed Atlantic Stainless Steel Electrode E308L-16 2.5/3.2/4.0mm Manufacturer OEM Rutile Coated Pressure Welding Rod

Adhering into the principle of “quality, provider, performance and growth”, we now have gained trusts and praises from domestic and intercontinental consumer for Well-designed Atlantic Stainless Steel Electrode E308L-16 2.5/3.2/4.0mm Manufacturer OEM Rutile Coated Pressure Welding Rod, Our experienced complex workforce might be wholeheartedly at your support. We sincerely welcome you to definitely stop by our web site and company and mail us your inquiry.

Adhering into the principle of “quality, provider, performance and growth”, we now have gained trusts and praises from domestic and intercontinental consumer for China Welding Rod and E308L-16, We strive for excellence, constant improvement and innovation, is committed to make us the “customer trust” and the “first choice of engineering machinery accessories brand” suppliers. Choose us, sharing a win-win situation!

Application&Standard&Note:

1. Suitable for petrochemical, pressure vessel, food machinery, medical equipment, fertilizer and other industries, welding 18% CR-8% Ni stainless steel (SUS304L, etc.)

2. The standard we met: GB/T983 E308L-16, AWS A5.4 E308L-16 & A5.4M E308L-16, ISO3581-A:E(19 9 L) R 1 2, ISO3581-B:ES308L-16, JIS Z3221 ES308L-16

E308L-16 was developed for welding 304L ,this electrode deposits a maximum of 0.04% carbon in the weld metal, This welding electrode is used extensively for welding of chemical plant equipment and may be used successfully for welding types 321 and 347 steel grades, This welding rod minimizes the formation of chromium carbides in the weld metal.

Features

1. Titanium calcium stainless steel electrode, the main composition is low carbon-18Cr-9%Ni-4%;

2. Stable arc, beautiful forming, fine ripples, few splashes, easy de-slagging, good fire resistance of drug skin, good stomatal resistance.

3. Stable mechanical properties, X-ray pass rate is high.

Stick Electrodes, AWS Classification E308-16, Material Stainless Steel, Process Stick Welding (SMAW), For Material Type Stainless Steel to Stainless Steel, Welding Current Designation AC, DCEP, For Welding Position Flat, Horizontal, Overhead, Vertical-Up

E308-16 stainless steel welding electrode is a kind of Titanium calcium type coating Cr18Ni9 stainless steel electrode, The deposited metal has good mechanical properties and intergranular corrosion resistance,It has good welding performance and porosity resistance, Heat resistance coating and crack resistance. AC/DC+ both can be applied.

Company & Factory

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.04 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-12.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| AWS RULES | 0.04 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| EXAMPLE VALUE | 0.029 | 0.89 | 0.75 | 19.7 | 9.5 | 0.01 | 0.024 | 0.004 | 0.1 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | - | 510 | - | - | 30 | |||||||||

| AWS RULES | - | 520 | - | - | 30 | |||||||||

| EXAMPLE VALUE | - | 595 | - | - | 42 | |||||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

PACKING DETAILES:

| SEPCIFICATION | LENGTH | PCS/1KG | WEIGHT/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

NOTE:

H/W: horizontal position welding

O/W: over-head position welding

Typical Cases

Certificate

Adhering into the principle of “quality, provider, performance and growth”, we now have gained trusts and praises from domestic and intercontinental consumer for Well-designed Atlantic Stainless Steel Electrode E308L-16 2.5/3.2/4.0mm Manufacturer OEM Rutile Coated Pressure Welding Rod, Our experienced complex workforce might be wholeheartedly at your support. We sincerely welcome you to definitely stop by our web site and company and mail us your inquiry.

Well-designed China Welding Rod and E308L-16, We strive for excellence, constant improvement and innovation, is committed to make us the “customer trust” and the “first choice of engineering machinery accessories brand” suppliers. Choose us, sharing a win-win situation!

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.04 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-12.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| AWS RULES | 0.04 | 0.5-2.5 | 1.00 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| EXAMPLE VALUE | 0.029 | 0.89 | 0.75 | 19.7 | 9.5 | 0.01 | 0.024 | 0.004 | 0.1 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | - | 510 | - | - | 30 | |||||||||

| AWS RULES | - | 520 | - | - | 30 | |||||||||

| EXAMPLE VALUE | - | 595 | - | - | 42 | |||||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

PACKING DETAILES:

| SEPCIFICATION | LENGTH | PCS/1KG | WEIGHT/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

NOTE:

H/W: horizontal position welding

O/W: over-head position welding